In the fast-evolving electronics industry, the demand for efficient solutions is ever-growing. Experts are looking toward turnkey PCB assembly as a critical component in meeting these needs. John Carter, a well-known figure in the field, once remarked, “Turnkey PCB assembly can significantly reduce time-to-market for new products.” This statement underscores the necessity of integrated solutions in today’s competitive landscape.

The advantages of turnkey PCB assembly are clear. Companies benefit from a streamlined process that merges design and production phases. This cohesion not only enhances efficiency but can also lead to cost savings. However, challenges exist. The industry often faces unexpected delays due to supply chain issues. Companies must be ready to adapt quickly and find innovative solutions.

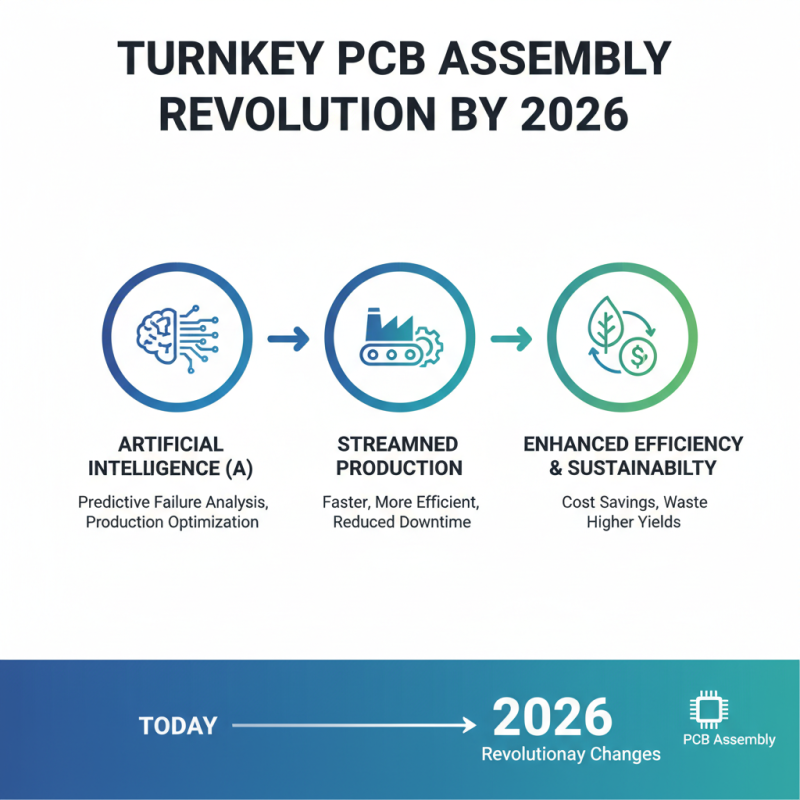

Looking ahead to 2026, several trends are emerging. Automation and AI are expected to play pivotal roles in optimizing production. Yet, it is essential to reflect on the importance of maintaining quality amidst rapid advancements. Balancing innovation with reliability remains a pressing concern for many businesses. Turnkey PCB assembly continues to be a focal point in navigating these complex challenges.

The electronics industry is on the brink of revolutionary changes in turnkey PCB assembly solutions by 2026. Emerging technologies are poised to streamline production processes and enhance efficiency. Among these technologies, artificial intelligence stands out. AI can analyze data to predict failures and optimize production schedules. This not only saves time but also reduces waste, making assembly more efficient.

Additive manufacturing is another trend to watch. This technology allows for rapid prototyping and customized designs, which can lead to innovative products. It also enables easier adjustments to designs without lengthy retooling processes. The speed of innovation could increase drastically.

**Tips:** Embrace AI tools in your assembly line. They can identify anomalies early, preventing costly errors later. Also, consider investing in additive manufacturing. It may require upfront costs but pays off with agility in design. Stay updated on these trends; being reactive is no longer enough.

Sustainability in PCB assembly is gaining traction. As the electronics industry evolves, practices for eco-friendly manufacturing are critical. Companies are now exploring ways to reduce waste and energy consumption. This leads to a more sustainable future for electronics.

One focus area is the choice of materials. Using recyclable components helps minimize environmental impact. Consider using lead-free solder. It's safer and better for the planet. Design choices also matter. Smaller PCB designs require fewer resources.

Tips: Always assess your supply chain. Seek suppliers committed to sustainable practices. Regularly review your processes. Identify areas that need improvement. Small changes can have a big effect. Remember, every step towards sustainability counts.

Another key aspect is electronic waste. Innovating in recycling practices can help. More companies are working on take-back programs. This creates a closed-loop system for materials. Educational resources are also vital. Train employees on sustainable practices. Awareness can drive significant change.

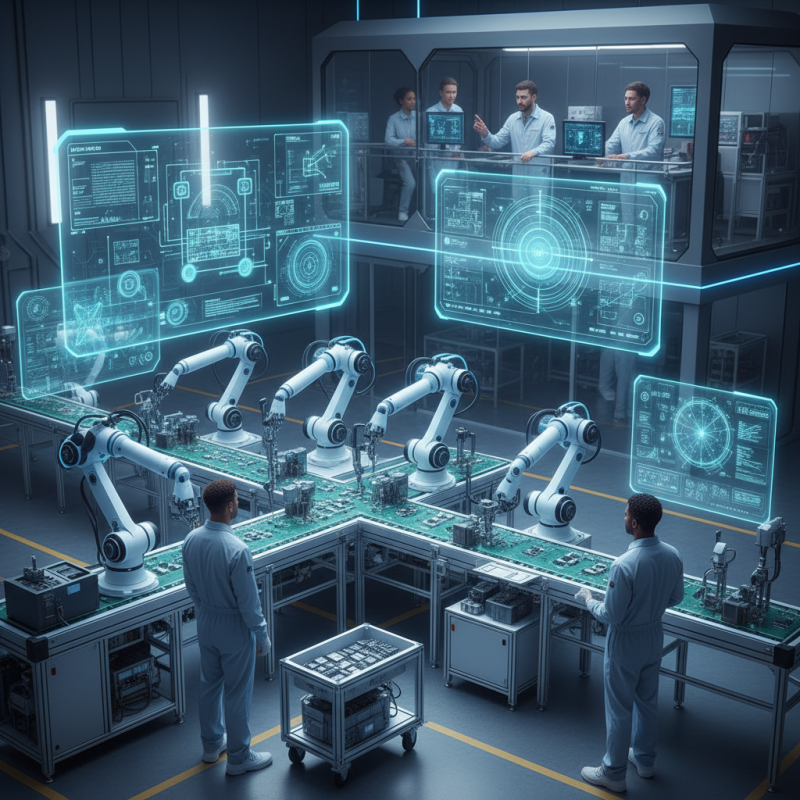

In 2026, advancements in automation and robotics significantly impact PCB assembly solutions. According to a recent industry report, automated systems can reduce production time by up to 40%. Many companies are adopting robotic arms for tasks like component placement and soldering. This shift increases efficiency and often enhances quality.

However, fully embracing automation poses challenges. Not all facilities can easily integrate new technologies, due to varying levels of existing infrastructure. The initial investment may deter small to medium-sized enterprises. Furthermore, workforce training is crucial as skilled operators are still needed to manage these systems effectively.

As electronics demand rises, streamlined operations become vital. An industry study indicated that nearly 70% of manufacturers prioritize automation for scalability. The integration of AI with robotics can optimize production further. Yet, companies must remain vigilant. Continuous monitoring of these systems is essential to prevent potential errors. A balance between automation and human oversight is necessary for ultimate success.

| Trend | Description | Impact on Production | Projected Growth (%) |

|---|---|---|---|

| Automation Integration | Incorporating advanced automated systems for handling PCB assembly. | Enhances assembly speed and accuracy. | 15% |

| Robotics Deployment | Utilizing robotics to streamline repetitive tasks in the assembly line. | Reduces labor costs and increases efficiency. | 20% |

| AI in Quality Control | Implementing AI algorithms for real-time defect detection. | Improves product quality and reliability. | 25% |

| 3D Printing for Prototyping | Using 3D printing techniques for rapid prototyping of PCBs. | Speeds up the development process. | 30% |

| Sustainability Practices | Adopting sustainable materials and processes in PCB manufacturing. | Meets environmental regulations and consumer demand for green products. | 18% |

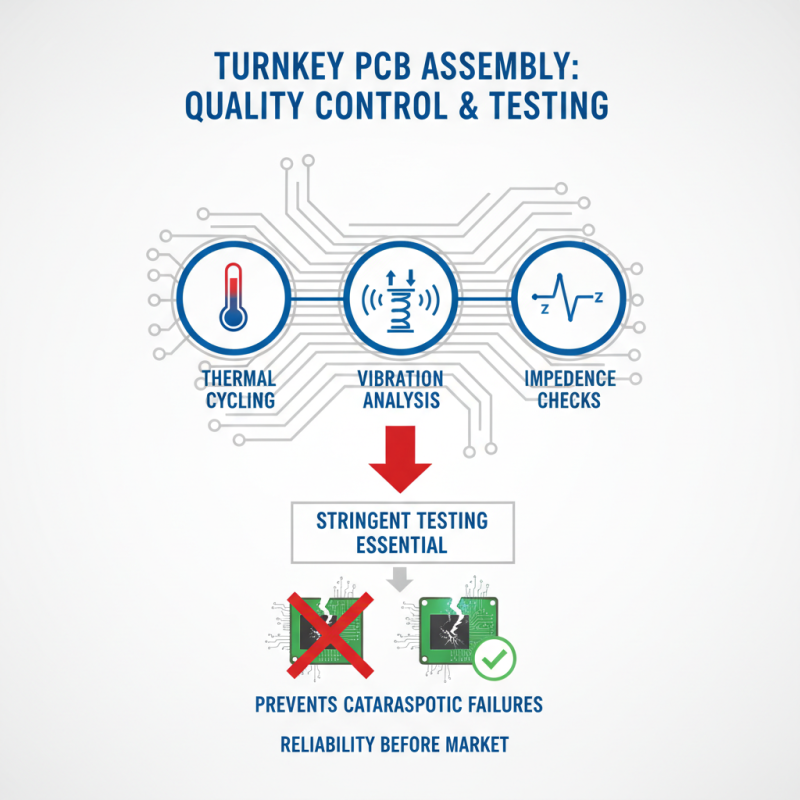

In the rapidly evolving electronics industry, quality control and testing have become paramount in turnkey PCB assembly solutions. A single defect in a printed circuit board can lead to catastrophic failures in devices. Therefore, stringent testing processes are essential before any product reaches the market. These tests often include thermal cycling, vibration analysis, and impedance checks to ensure reliability.

Many companies still overlook crucial steps in the quality control process. Some may rely too heavily on automated systems, neglecting the human factor. Human inspectors can catch subtle defects that machines miss. Additionally, the lack of standardized testing protocols can lead to inconsistency in product quality. Investing in comprehensive training for employees is vital. This ensures they understand the importance of each test they conduct and the implications of poor quality.

Having robust quality control measures means developing a culture of accountability and continuous improvement. Regular audits of testing processes can help identify gaps. The solution is not just about technology; it’s about fostering a mindset that prioritizes precision and excellence. By addressing these issues, companies can enhance their reputation and build long-lasting relationships with clients.

The demand for custom PCB assembly services is expected to surge in 2026. This growth is driven by several market trends, including the rise of IoT devices and electric vehicles. More manufacturers seek tailored solutions that meet specific design requirements. As technology evolves, standards for PCB design and assembly are also changing. This creates both opportunities and challenges in the industry.

**Tip:** Always stay updated on the latest technology trends. This knowledge helps in making informed decisions regarding custom PCB needs.

Emerging markets are also contributing to this demand. Countries are ramping up their electronic production capabilities. This shift allows for more localized assembly solutions. However, sourcing materials can still be a struggle. Balancing quality with cost remains a significant challenge for many businesses.

**Tip:** Assess your supply chain regularly. Identifying potential risks can help mitigate disruptions.

In addition, sustainability is becoming crucial. Consumers are more environmentally conscious. Manufacturers must innovate to reduce waste and improve energy efficiency. They need to ensure compliance with environmental regulations. This necessity drives the adoption of new technologies in PCB assembly.