In the fast-paced world of electronics, fast PCB designs are vital for success. Industry expert Dr. Emily Tran once said, “Speed is the new currency in PCB production.” As we approach 2026, the demand for efficient designs continues to grow. This requires an innovative mindset and agility in production processes.

Fast PCBs are not just about speed; they also encompass quality and reliability. Companies are under pressure to deliver products faster than ever. Yet, there is often a struggle to balance speed with design integrity. A poorly executed fast PCB can lead to costly errors and delays.

Efficiency in electronics production hinges on the right designs. Factors like material selection and layout planning matter. Users must be aware of their choices and their impacts. The challenge lies in mastering both speed and precision. As the industry evolves, reflection is vital. What lessons can we learn from previous fast PCB projects?

In 2026, fast PCB design has become essential for efficient electronics production. Rapid advancements in technology demand shorter lead times. Designers face pressure to create high-quality PCBs quickly. The industry is evolving, but challenges persist.

Toolsets have improved significantly. Modern design software accelerates layout processes. Automated routing saves time and minimizes errors. Yet, designers often encounter bottlenecks. Communication among teams can break down. Misunderstandings lead to rework, impacting timelines. This reveals the need for better collaboration.

Prototyping methods are evolving too. 3D printing allows for quick iterations. Designers can physically test concepts before full production. However, this doesn't eliminate the need for thorough testing. Many overlook this step, risking product reliability. Addressing these gaps is critical for future success in fast PCB design.

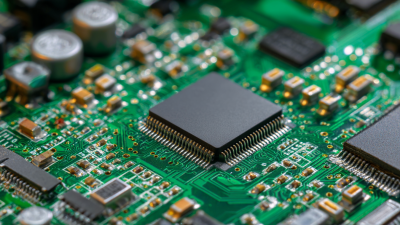

Efficient PCB designs are crucial for modern electronics production. These designs must prioritize both functionality and manufacturability. A key feature of effective PCBs is minimalistic layout. A cluttered design can lead to production delays. Each component should be thoughtfully placed to ensure easy access for assembly and testing.

Thermal management is another critical aspect. Heat accumulation can damage electronic components. Integrating heat sinks and thermal vias helps dissipate heat. It's essential to consider material choices. Some materials perform better under high temperatures. But, their cost can also be higher, leading to budget constraints. Design teams need to find a balance.

Furthermore, trace width and routing play a significant role. Narrow traces can cause issues, like high resistance or overheating. Yet, wide traces may waste space. A careful analysis is necessary. Designers must often rethink their choices. Prototypes may reveal weaknesses in early designs, which can be frustrating yet vital for improvement. Effective collaboration between engineers can lead to better outcomes but is sometimes lacking. Open communication is essential to refine designs for efficiency.

The landscape of PCB production is rapidly evolving due to innovative technologies. Data from industry reports indicate that automation and AI-driven processes are boosting efficiency. For instance, automated inspection systems can reduce errors by up to 30%. This precision is critical as the demand for smaller, more complex circuits grows.

Additive manufacturing also plays a significant role. A recent study suggested that 25% of PCBs could be produced using 3D printing in the next few years. This method allows for intricate designs that traditional methods struggle to achieve. However, challenges remain. Materials need to improve to withstand high frequencies and temperatures. Trade-offs between speed and quality often frustrate manufacturers.

Moreover, the integration of IoT in PCB production promises real-time monitoring. This dynamic could enhance productivity by identifying bottlenecks instantly. Yet, there's a learning curve. Many companies lack the technical skills to implement these technologies effectively. The transition is not easy, and the potential for disruption is significant. Collaboration and training will be essential to navigate this transformation.

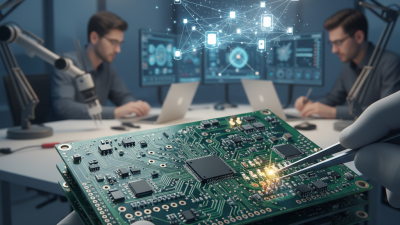

In the fast-paced world of electronics, rapid prototyping is crucial. It helps bring ideas to life at lightning speed. Engineers often use online tools for quick design adjustments. This usually enables testing concepts before production. However, relying solely on digital simulations can lead to inaccuracies. Physical prototypes are essential for identifying flaws.

Testing prototypes early in the design phase saves time and resources. It allows designers to explore different layouts or materials. Many opt for a simple breadboard setup that can be built in a matter of hours. But what happens when things go wrong? Sometimes, components do not fit as planned. Design oversights can lead to costly revisions later.

Iterative testing improves accuracy, yet it often comes with its challenges. Each revision might reveal new issues. Diagnostics can be time-consuming, pushing deadlines back. Balancing speed and precision is tough. Designers must learn to adapt quickly, reflecting on past mistakes. Through this process, effective solutions can evolve, ultimately leading to better outcomes.

| Design Feature | Description | Material Used | Production Time (Days) | Testing Method |

|---|---|---|---|---|

| High-Density Interconnect (HDI) | Suitable for compact devices, allowing more connections in a smaller area. | FR-4 | 14 | X-Ray Inspection |

| Flexible PCBs | Ideal for applications requiring bending and flexing. | Polyimide | 10 | Functional Testing |

| Multilayer Boards | Used for complex designs that require multiple layers. | Fiberglass | 21 | Environmental Testing |

| Rigid PCBs | Commonly used for most electronic products. | FR-4 | 7 | Visual Inspection |

| Embedded Component Design | Components embedded within the PCB layers to save space. | Multilayer Material | 18 | Impedance Testing |

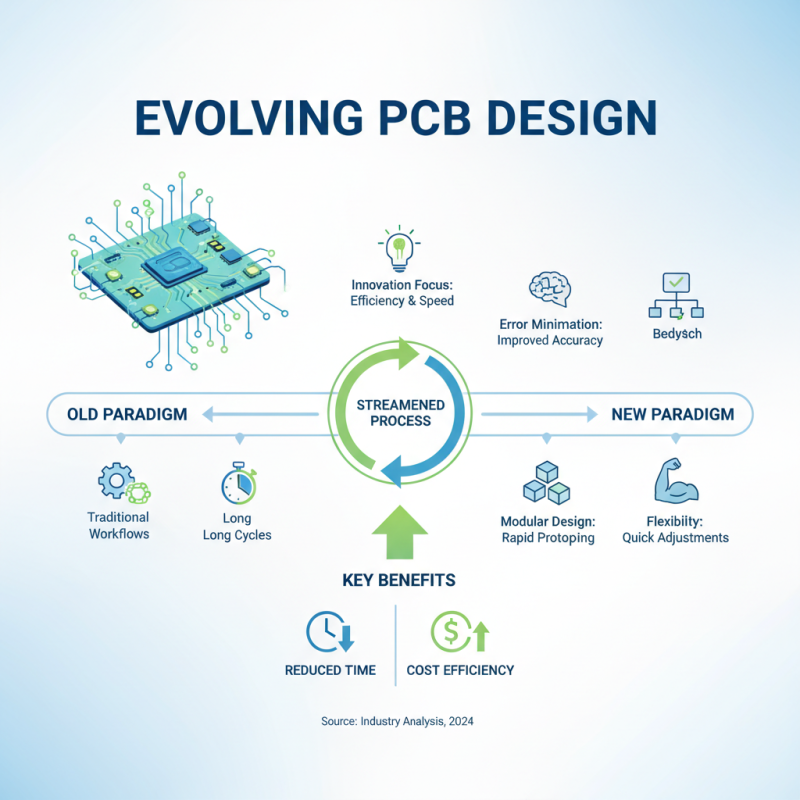

The landscape of PCB design is evolving rapidly. Innovations aim to enhance efficiency and reduce production times. Designers now focus on streamlining workflows and minimizing errors. Techniques like modular designs help in achieving rapid prototyping. This shift brings flexibility, allowing quick adjustments to meet project specifications.

In addition, sustainable practices are gaining traction. Designers are exploring eco-friendly materials to reduce electronic waste. This trend poses challenges, such as balancing durability and sustainability. Adopting a circular economy mindset can be difficult, yet necessary. Striking this balance is crucial for future growth.

Automation plays a pivotal role in modern design. Advanced tools and software facilitate faster iterations, but they also bring a learning curve. Designers need to adapt and refine their skills continually. Collaboration between engineers and designers becomes essential in this fast-paced environment. Creating efficient PCBs requires ongoing reflection and adaptation.