Choosing the best PCB fabrication and assembly services can be challenging. With many options available, you must make an informed decision. The quality of your printed circuit boards directly impacts your project's success.

Evaluating potential providers is essential. Look for companies with industry experience and good reviews. Check their manufacturing capabilities and technology used. Are they equipped to handle your specifications? Poor choices can lead to delays and increased costs.

Reflect on your needs and budget. Prioritize quality, but remember that cheaper options may not always be the best. Consider lead times and customer support as well. Selecting the right PCB fabrication and assembly service requires careful thought and research.

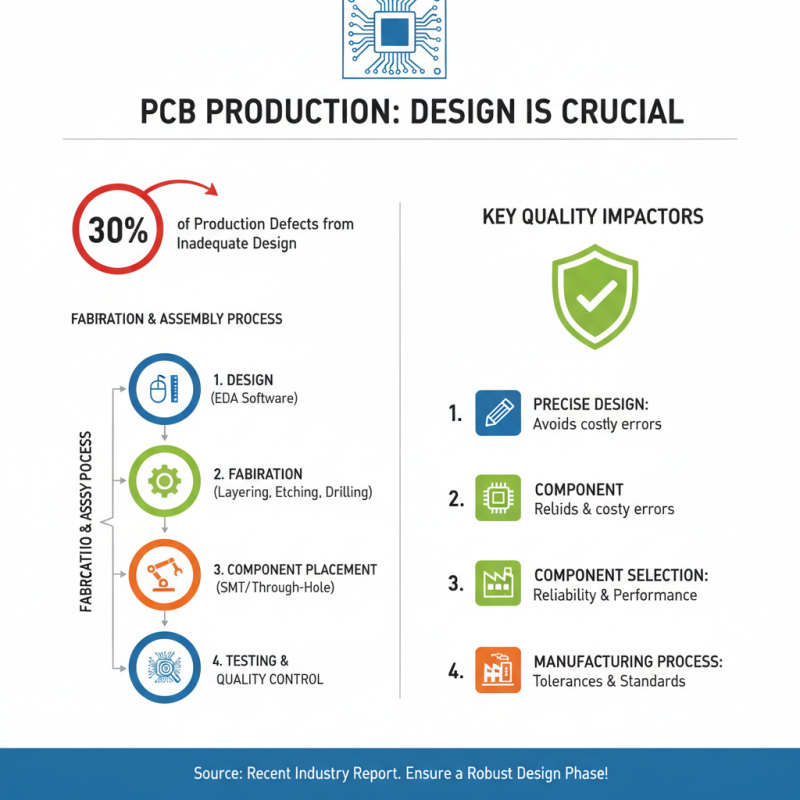

The PCB fabrication and assembly process is complex. It involves several key components that can significantly impact the final product's quality. According to a recent industry report, around 30% of production defects stem from inadequate PCB design. Ensuring a precise design phase is crucial to avoid costly errors later.

After the design, materials must be sourced carefully. The choice of substrates and conductive materials can influence performance and durability. It’s noted that 48% of companies experience delays due to material shortages. These setbacks can frustrate timelines and affect project viability.

The assembly phase introduces its own challenges. The soldering process, whether through wave or reflow methods, can create unwanted defects if not monitored. Reports indicate that up to 15% of assembled PCBs may fail initial testing due to soldering issues. Regular quality checks are essential, yet many companies still overlook this step, leading to potential failures in the field.

When evaluating PCB manufacturers, quality standards and certifications play a crucial role. Look for manufacturers who adhere to ISO 9001 standards. This certification indicates a commitment to maintaining consistent quality. Ensuring adherence to IPC standards is equally significant. IPC certification demonstrates that a manufacturer meets industry benchmarks for performance and reliability.

Not all manufacturers will have the same level of certification. This inconsistency can make choosing the right provider challenging. Some may claim high quality but lack proper certifications. This discrepancy can lead to unexpected issues later in the production phase. Always verify certification documents before proceeding. It might save you from future headaches.

You should also consider the manufacturer's experience. A company with a long history is likely to understand the nuances of quality control. However, newer firms may have updated technologies. Their lack of experience might lead to oversight. Assessing reviews and customer feedback can offer insights into potential gaps. It's essential to weigh both established reliability and innovative approaches when making your choice.

| Criteria | Description | Rating (1-5) |

|---|---|---|

| Quality Standards | ISO 9001, IPC-A-600, IPC-A-610 certifications ensure quality compliance. | 5 |

| Turnaround Time | Time taken to complete fabrication and assembly process. | 4 |

| Cost Effectiveness | Comparison of costs for services offered versus industry average. | 4 |

| Customer Support | Quality of service and assistance provided during and post-production. | 5 |

| Technology Used | Modern equipment and technology level in PCB manufacturing. | 5 |

| Prototyping and Testing | Availability of prototyping services and testing quality post-production. | 4 |

When evaluating PCB fabrication and assembly services, cost analysis is essential. Industry reports show that PCB fabrication costs can range from $2 to $10 per square inch. Many factors influence these prices, including the complexity of the design, the materials used, and the volume of production. Pricing can vary dramatically based on the provider's capabilities and location. Understanding these elements helps businesses avoid unexpected costs.

Assembly services often add another layer of expenses. Reports indicate that assembly costs can range from $0.10 to $6 per component. This wide variability comes from different assembly techniques and component sourcing. For basic assembly, prices may be on the lower end. Yet, specialized processes like surface-mount technology can drive costs up significantly. Paying attention to details in your assembly needs can help budget more accurately.

In the quest for quality services, the cheapest option is not always the best. Poor fabrication quality can lead to higher long-term costs due to failures and rework. It’s critical to balance cost with quality and lead times. Knowing when to invest in better quality can prevent delays down the line. Careful reflection on these aspects can aid in making a well-informed choice.

When selecting PCB fabrication and assembly services, understanding lead times and production capacities is crucial. Many companies offer quick turnarounds, but can they consistently meet that promise? Consider the complexity of your design. More intricate boards typically require longer lead times. Establish a clear timeline based on your project demands.

Keep in mind, setting realistic expectations is essential. Some vendors may overstate their production capabilities. Do your research and read client reviews. Ask about their average lead times for similar projects. This will help you gauge their reliability.

Tips: Always communicate your deadlines clearly. This ensures that both parties are aligned on expectations. If your design changes mid-project, discuss how that impacts the lead time. Maintaining open communication throughout the process can prevent misunderstandings. Remember, flexibility can enhance the collaboration, but it might stretch timelines too.

This chart illustrates the expected lead times in days and production capacities in units per week based on different order sizes for PCB fabrication and assembly services. Make sure to set realistic expectations when planning your projects!

When selecting PCB fabrication and assembly services, customer support and communication play vital roles. An effective collaboration can significantly impact the project timeline and final product quality. Quick and clear responses from the service provider can make all the difference. Imagine waiting days for a reply when a simple question could save hours. This delay could affect your overall schedule.

Consider how the service provider communicates technical details. Do they use clear language? Are they open to questions? Engaging discussions can lead to better design suggestions. Companies often overlook this aspect and later regret it. Good communication means more than just answering questions; it involves understanding your needs.

Additionally, miscommunication can lead to costly mistakes. A small design change overlooked in a conversation can result in rejects during production. Reflect on past experiences—were you satisfied with your providers? If not, it might be time to reassess your priorities in communication. Strong communication helps build trust. Be proactive in seeking a partner that values this. The right choice can lead you to innovation and timely delivery.