Choosing the right printed circuit board assembly service is crucial for your project's success. The global market for printed circuit boards (PCBs) reached $69.2 billion in 2020, according to a study by Allied Market Research. As demand grows, selecting a service that meets quality and efficiency becomes vital.

David F. Olsson, a leading expert in the PCB industry, states, "Quality assembly can make or break your product." This emphasizes the importance of partnering with the right service. It's not merely about cost; factors such as turnaround time and manufacturing capabilities matter deeply. A poor choice can lead to delays and increased costs, impacting your bottom line significantly.

Opt for a PCB assembly service that provides thorough communication and clear timelines. Be wary of those that promise unusually fast delivery without proper checks in place. The details matter more than many realize. Trusting your instincts and doing digital due diligence can lead to better decisions. Remember, investing time in this choice will pay off in the long run.

Choosing the right printed circuit board (PCB) assembly service begins with understanding your specific requirements. Assessing your project scale is crucial. Are you working on a small prototype or a large production run? This will greatly affect the capabilities you seek in a service provider. Think about the complexity of your design. Does it involve advanced technology or are the components simpler? Clear understanding leads to better choices.

Tip: Always outline your project needs in detail. This helps in getting accurate quotes and timelines. Communicating with your assembly service about your vision is key.

Consider the materials you require. Different projects may need different substrates or components. Be specific about your requirements, even down to the type of solder and finishes. Some services may not offer adequate options. Reflect on your budget as well. Cheaper services may lead to quality issues. Balancing cost with quality is vital for successful projects.

Tip: Assess previous work and client reviews of potential services. It's about finding the right fit, not just the cheapest price. Understanding your own expectations is essential. Don't rush this process. Mistakes in the early stages can lead to costly fixes later.

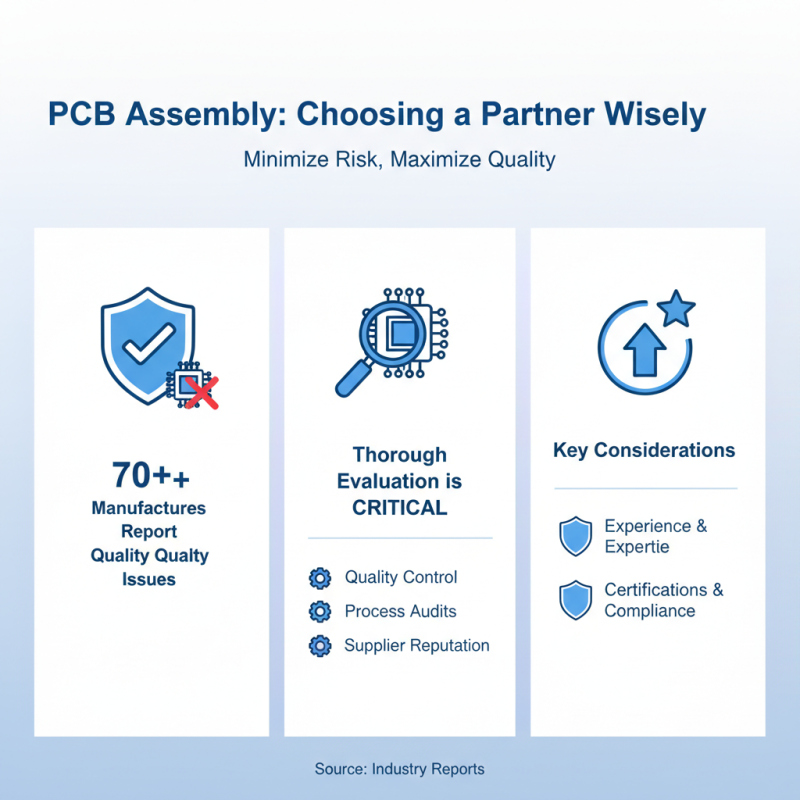

Evaluating PCB assembly service providers requires careful consideration. Industry reports indicate that over 70% of manufacturers report issues in quality control when selecting a service partner. This highlights the importance of thorough evaluations.

Start by assessing the provider's experience. Companies with at least five years in the industry often show better reliability. A report from the IPC states that 65% of successful projects come from experienced partners. Look for client reviews and case studies as they provide insights into past performance and potential risks.

Quality assurance processes are another critical factor. According to a recent survey, 80% of companies prioritize ISO certifications when choosing a PCB assembly service. They are linked to improved quality and fewer errors. Ensure the provider maintains robust testing procedures. However, finding the right balance between cost and quality can be challenging. Many firms struggle with this and face unexpected expenses. Make sure to ask for detailed breakdowns in quotes but remain skeptical of prices that seem too low.

When selecting a printed circuit board (PCB) assembly service, understanding quality standards is crucial. Quality certifications, such as ISO 9001, ensure that a service provider adheres to stringent processes. Reports indicate that companies with these certifications experience up to 15% lower defect rates in their assemblies. This statistic highlights the importance of assessing a potential partner's adherence to established standards.

Another key aspect is the IPC certification. The IPC-A-610 standard sets the criteria for the acceptability of electronics. According to industry surveys, nearly 70% of manufacturers prefer services with IPC certification. This preference underscores the reliability that comes with recognized quality benchmarks. However, not all services maintain these standards consistently. Some may claim certifications without regular verification, leading to potential risks in quality control.

It’s essential to ask potential providers about their quality assurance processes. Transparency is critical. Understand how frequently they perform audits. A service must not only have certifications but also reflect commitment in everyday operations. Sometimes, companies invest heavily in marketing their quality but fail in realistic application. Assessing quality involves critical reflection on both the certifications and the company's track record.

When selecting a printed circuit board (PCB) assembly service, costs and timelines can significantly impact your project. Industry reports indicate that assembly costs can vary widely, ranging from $0.01 to $0.50 per component, depending on complexity. For example, basic designs are often cheaper, while those with intricate layouts incur higher fees.

Timelines are equally crucial. The average turnaround time for PCB assembly is estimated to be 2-4 weeks. However, expedited services may reduce this to 1 week, albeit at a higher cost. Companies must weigh the expense of quick turnarounds against project deadlines. Rushed timelines can lead to oversights, impacting quality.

Many reports highlight that around 30% of projects face delays. Poor communication with assembly services is often a primary cause. To mitigate risks, invest time in choosing the right service. Inspect their past projects. Check reviews, and be precise with your specifications to avoid costly mistakes. Balancing cost and timeline efficiency can prevent future headaches.

Effective communication is vital when selecting a printed circuit board assembly (PCBA) service. A study shows that 75% of project delays arise from poor communication. The provider’s responsiveness impacts your project's success directly. A quick reply to emails or calls can solve many issues before they escalate. Transparency from providers fosters trust. Regular updates about production status can alleviate concerns.

Support during the assembly process is equally crucial. Reports indicate that projects requiring ongoing support are 40% more likely to succeed when the provider is accessible. It is important to ask about their support mechanisms. Whether it's dedicated account managers or online portals, having robust support options matters. Unforeseen challenges often arise. A provider that responds swiftly can help navigate these.

Inadequate communication can lead to misunderstandings. When issues go unaddressed, costs can spiral. A disorganized process is detrimental for both parties. Select a PCBA service that emphasizes communication. Pay attention to their approach to support and information sharing. Clear communication is not an option, but a necessity in this industry.