Circuit card assembly (CCA) is a vital process in electronics manufacturing. As an integral part of electronic devices, CCA involves the assembly of electronic components onto printed circuit boards (PCBs). According to a report by Research and Markets, the global CCA market is projected to reach $24 billion by 2027, highlighting its significance in the rapidly evolving tech landscape.

Jane Smith, a leading expert in electronics manufacturing, states, "Circuit card assembly is the backbone of modern electronics." This not only emphasizes CCA's crucial role but also underlines the complexity involved in ensuring quality and reliability. Many companies struggle with the need for high precision in their assembly lines. In an industry where errors can be costly, maintaining standards is often a challenge.

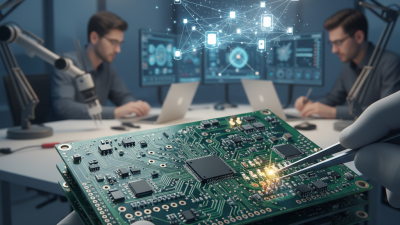

The assembly process requires skilled technicians and advanced machinery. However, achieving consistency and quality can be elusive. Companies must invest time and resources to refine their CCA practices continuously. The journey toward excellence in circuit card assembly isn't always linear, requiring flexibility and adaptation to technological advancements.

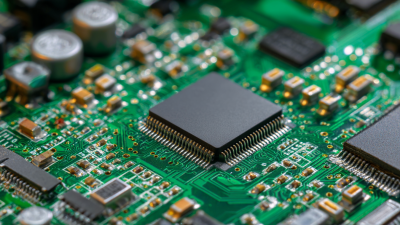

Circuit Card Assembly (CCA) is a crucial process in electronics. It involves mounting electronic components onto a printed circuit board (PCB). This assembly enables the creation of the devices we rely on daily. Smartphones, computers, and many other electronics stem from this core process.

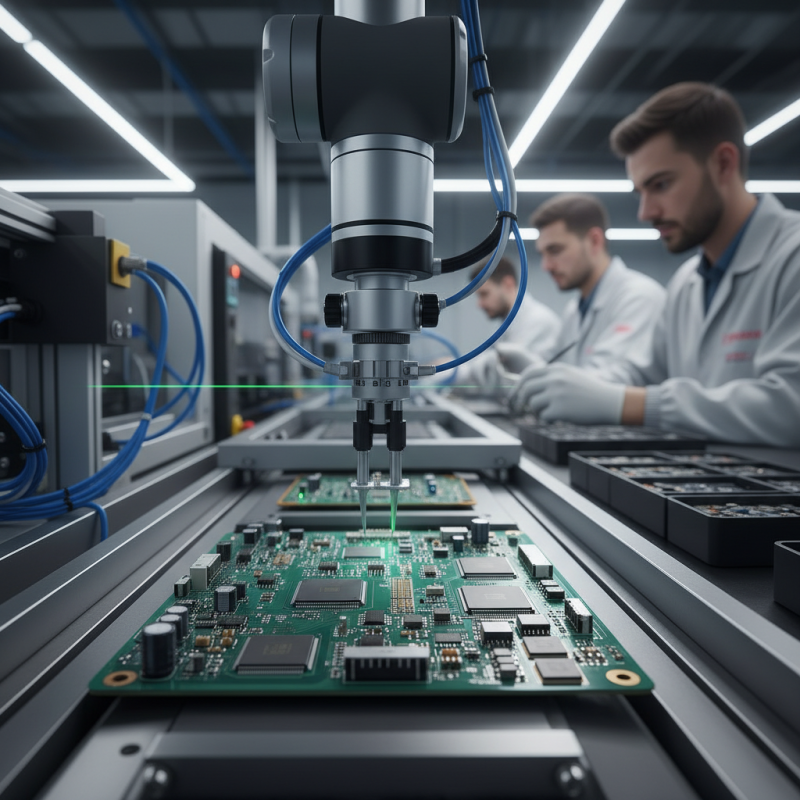

During CCA, soldering techniques are employed to secure components. Automated machines often assist, improving speed and precision. However, this can lead to mistakes. Misalignment or incorrect soldering can cause significant issues later. The process requires attention to detail. One small error can mean defective products or costly recalls.

The importance of CCA cannot be understated. It is the backbone of modern electronic devices. A well-assembled circuit card ensures functionality and longevity. Conversely, a poorly executed assembly can lead to failures. Testing is essential, but it can’t catch every potential flaw. Continuous improvement in CCA practices is needed. Each iteration brings the opportunity for better results.

| Dimension | Description | Importance |

|---|---|---|

| Definition | The process of assembling electronic components onto a printed circuit board. | Essential for creating functional electronic devices. |

| Components | Includes resistors, capacitors, integrated circuits, and connectors. | Diverse component types allow for versatile applications. |

| Process Steps | Design, fabrication, assembly, and testing of circuit boards. | Critical to ensure quality and reliability of electronics. |

| Technology Used | Surface-mount technology (SMT) and through-hole technology. | Advancements lead to smaller and more efficient devices. |

| Applications | Used in consumer electronics, automotive, medical, and industrial sectors. | Impact on various industries enhancing functionality and reliability. |

Circuit card assembly (CCA) is essential for modern electronics. Understanding the components involved helps in appreciating its role. A CCA typically includes various elements such as resistors, capacitors, and integrated circuits. Each component plays a critical role in circuit function.

Resistors limit current flow, while capacitors store energy. Integrated circuits combine multiple functions into a single unit, saving space. Proper placement of these components on the circuit board influences performance. However, mistakes can happen during assembly. Misalignment may occur, leading to circuit failures. Inspecting each component thoroughly is vital.

Choosing the right materials is crucial too. The choice of substrates affects durability. For example, flexible circuits are beneficial for specific applications. Yet, they can be more challenging to assemble. The complexities of CCA involve constant learning. Engineers must adapt to new technologies and techniques, avoid complacency, and strive for precision. Each assembly is a step towards innovation in electronics.

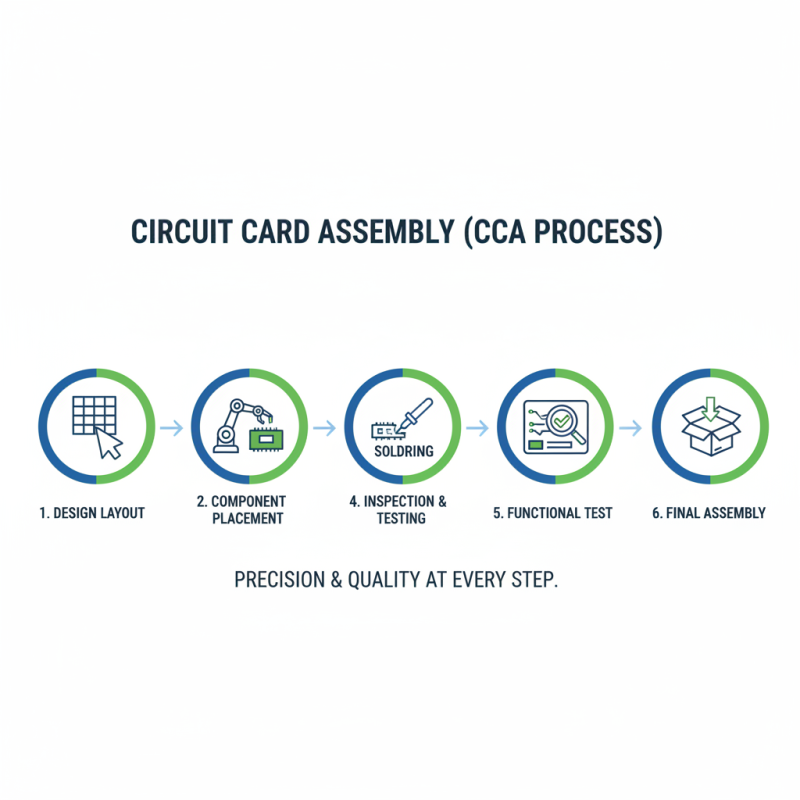

Circuit Card Assembly (CCA) is a crucial process in electronics. It involves several distinct steps that ensure the proper functioning of electronic devices. Initially, the design layout is created, detailing where components will be placed on the circuit board. This stage requires precision and skills, as mistakes here can lead to significant errors in the end product.

Next, the components are sourced and prepared. Each part must be inspected for quality. Issues with components can result in malfunctioning devices. After preparation, the actual assembly begins. Components are soldered onto the circuit board. This step demands attention to detail, as improper soldering can cause short circuits or loose connections.

Finally, testing is essential. The assembled circuit card must be tested for functionality. It's common to find faults during this process. Reflection on these errors leads to improvements in future assemblies. The importance of CCA cannot be overstated, as it lays the foundation for reliable electronic devices used in daily life. Each step, with its challenges, helps enhance overall product quality.

Circuit Card Assembly (CCA) plays a crucial role in the electronics industry. According to a recent report by Markets and Markets, the global CCA market is expected to reach $120 billion by 2025, growing at a CAGR of 5.6%. This growth reflects the increasing demand for compact, efficient electronic devices in various sectors like telecommunications and consumer electronics.

CCAs are essential for the functionality of modern devices. They enable the integration of various electronic components, such as resistors, capacitors, and microchips. The precision of these assemblies affects device performance and reliability. Yet, challenges persist. Quality control remains a significant issue, with defects potentially leading to device failures. The industry grapples with maintaining standards while innovating to meet rising consumer expectations.

Moreover, sustainability is becoming a priority. Many firms face pressure to adopt eco-friendly practices. A report from the International Electronics Manufacturing Initiative highlighted that approximately 30% of electronic waste comes from defective or obsolete circuit cards. Balancing innovation and sustainability remains a complex challenge in today’s electronic landscape.

Circuit Card Assembly (CCA) plays a vital role across various industries. In the automotive sector, for example, CCAs are integral to vehicle control systems.

According to Statista, the automotive electronics market is projected to reach over $250 billion by 2026.

These advancements improve safety and efficiency, yet challenges persist with sourcing high-quality components.

In medical devices, CCAs are crucial for functionality. Reports indicate a growing demand, with the medical electronics market expected to surpass $100 billion soon.

However, manufacturing inaccuracies can lead to device malfunctions. Ensuring precision in assembly is paramount.

Tips: Focus on quality control. Regular testing during assembly can reduce errors.

Also, invest in employee training. Knowledgeable workers boost assembly accuracy.

In the telecommunications industry, CCAs enable faster data transmission. The global telecom equipment market is expected to grow significantly.

Yet, adapting to rapid changes poses challenges for manufacturers. Staying updated with technology is essential.

Tips: Embrace new technologies. Continuous improvement can enhance production efficiency.

Don't underestimate the importance of R&D in CCA processes.