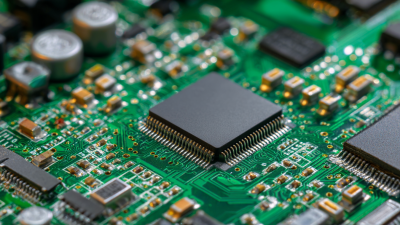

Choosing the right PC board for your projects can be challenging. Many factors come into play. A PC board, or printed circuit board, is crucial for electronic designs. Selecting the wrong board could lead to significant delays and complications.

When you consider a PC board, think about its size, material, and layout. Each project has its unique requirements. The right PC board can enhance functionality and performance. However, it's easy to overlook details, leading to mistakes. For instance, a poorly designed layout can cause signal interference.

Reflect on your needs and budget before making a decision. The perfect PC board should align with your project's goals. Remember that not all boards are created equal. Each choice comes with trade-offs. Embracing the complexity of this decision is essential for success.

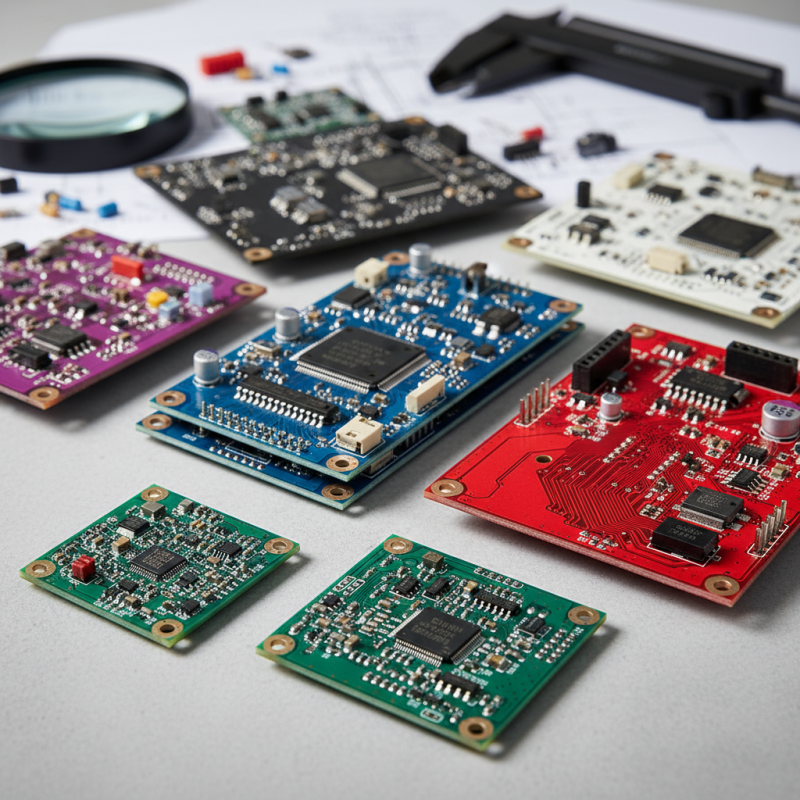

When choosing a PC board, it’s crucial to understand the various types available. There are printed circuit boards (PCBs), flexible PCBs, and rigid-flex PCBs. Each type serves distinct functions. Printed circuit boards are the most common. They’re designed for fixed electronic components. Flexible PCBs offer the advantage of bending and twisting, allowing for compact designs. Rigid-flex boards combine both qualities but can be complex.

Materials play an important role too. For instance, FR-4 is widely used for its good insulation properties. But there are many other materials. This can make decision-making hard, especially when balancing cost and performance. What if the material does not meet your heat specifications? Potential failures can arise if the choices are not carefully considered.

Another aspect to reflect on is the manufacturing process. Different boards require unique methods. Some might demand higher lead times. A simple design could turn into a complicated process if multiple revisions are needed. For example, if your design has errors, it can lead to delays. That’s why reflecting on your specific needs is essential before making a choice. Every project has its nuances.

When selecting the right PCB materials, electrical performance is crucial. Factors such as dielectric constant, thermal conductivity, and loss tangent should be evaluated carefully. A study by IPC revealed that over 50% of PCBs fail due to material selection issues. The right material improves signal integrity and reduces heat distribution.

Dielectric materials like FR4 are common for cost-effectiveness. However, they may struggle with high-frequency applications. For RF and microwave designs, consider using materials with a low dielectric constant, such as Rogers or Teflon. According to a recent study, using high-quality substrates can enhance performance by up to 40%.

Thermal conductivity is another key factor. It directly influences reliability and longevity. Boards that dissipate heat effectively reduce the risk of failure. Research from Mentor Graphics shows that inadequate heat management can decrease lifespan by nearly 30%. This emphasizes the need to evaluate thermal properties alongside electrical characteristics. In conclusion, thoughtful material selection based on these factors leads to greater project success.

| Material Type | Dielectric Constant (Dk) | Loss Tangent (Df) | Thermal Conductivity (W/mK) | Operating Temperature (°C) |

|---|---|---|---|---|

| FR-4 | 4.5 | 0.02 | 0.3 | 130 |

| Rogers 4350B | 3.48 | 0.003 | 0.25 | 280 |

| Taconic RF-60 | 6.15 | 0.0027 | 0.21 | 250 |

| PTFE (Teflon) | 2.1 | 0.001 | 0.17 | 260 |

| Polyimide | 3.00 | 0.004 | 0.15 | 200 |

When selecting a PCB for your project, analyzing layer count and size is crucial. A multi-layer board offers more complexity but increases production costs. If you're designing a compact device, a two-layer PCB may suffice. However, complex circuits with numerous components require additional layers. This can escalate the price significantly.

Tip: Consider your project's requirements carefully. A simple design can often meet your needs without the added costs of a multi-layer board.

Size also impacts your choices. A smaller PCB may be cheaper, but it limits placement options. If components are densely packed, heat dissipation could become an issue. Check for available space in your device's housing.

Tip: Sketch your layout before finalizing the design. Visualizing helps avoid mistakes and reduce complexity. Ultimately, balance functionality with cost. Each decision you make shapes the final outcome. Continuous iterations can lead to an optimal solution.

Choosing the right manufacturing process for your PC board is crucial. It directly impacts both quality and cost. Each method has pros and cons. For instance, using a high-speed process may reduce costs but could compromise the board’s integrity. On the other hand, a painstaking, quality-driven approach will yield a flawless product but increase expenses.

Consider your project’s specific needs. Are you prioritizing speed or precision? Sometimes, it’s tempting to choose the cheaper option. However, misjudgments can lead to future headaches. Components might fail, resulting in costly repairs. Balancing quality and cost involves making difficult decisions that demand reflection. You might find that a mid-range option meets most of your criteria without sacrificing too much.

Don’t forget to evaluate the long-term effects of your choice. A low-cost board might look attractive initially, yet hidden issues can arise. Recurring failures can damage your reputation. The manufacturing method you choose should align with your project’s goals. Ensuring that quality and cost are appropriately balanced is essential for success. Each project will require its own unique consideration, making flexibility key.

When designing a PCB, thermal management is crucial. Overheating can lead to failures in electronic components. Proper management prevents heat buildup. Assessing heat sinks and thermal vias should be part of your process. These elements help direct heat away from sensitive areas. Poor decisions here can ruin an entire project.

Consider the materials used in your PCB. Some materials dissipate heat better than others. A standard FR-4 might not suffice for high-power applications. In such cases, explore alternatives that offer better thermal conductivity. Analyze how the design itself affects heat flow. Isolate heat-generating components from sensitive ones. External factors, like airflow, can influence thermal performance too.

Testing is necessary. Simulate how your PCB will perform under heat stress. This can reveal potential issues early. You may find that your initial choices require adjustments. It’s a learning process, and not every design will be perfect. Reflection on past projects can inform your current decisions. Embrace the opportunity for improvement in thermal management.