In the realm of modern electronics, the evolution of PC boards has been a pivotal development, serving as the backbone for a plethora of devices that define our daily lives. According to a report by the research firm Grand View Research, the global printed circuit board (PCB) market size was valued at USD 60.13 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2028. This remarkable growth is a testament to the increasing demand for electronic devices and innovations in technology.

Experts in the field emphasize the crucial role that PC boards play in the advancement of electronics. Dr. Emily Chen, a leading authority in PCB technology, states, “The versatility and functionality of PC boards have made them essential for the integration of complex electronic systems." This sentiment underscores the significant impact that PC boards have on the efficiency and capability of modern electronics, driving innovations across various sectors, including consumer electronics, automotive, and telecommunications.

As the industry continues to evolve, the importance of understanding the intricacies and advancements of PC boards cannot be overstated. With emerging trends such as 5G technology and the Internet of Things (IoT) shaping the future, staying informed about the developments in PC board technology will be essential for stakeholders aiming to lead in the competitive electronics market.

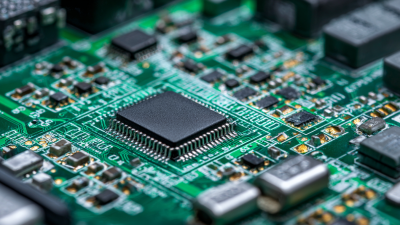

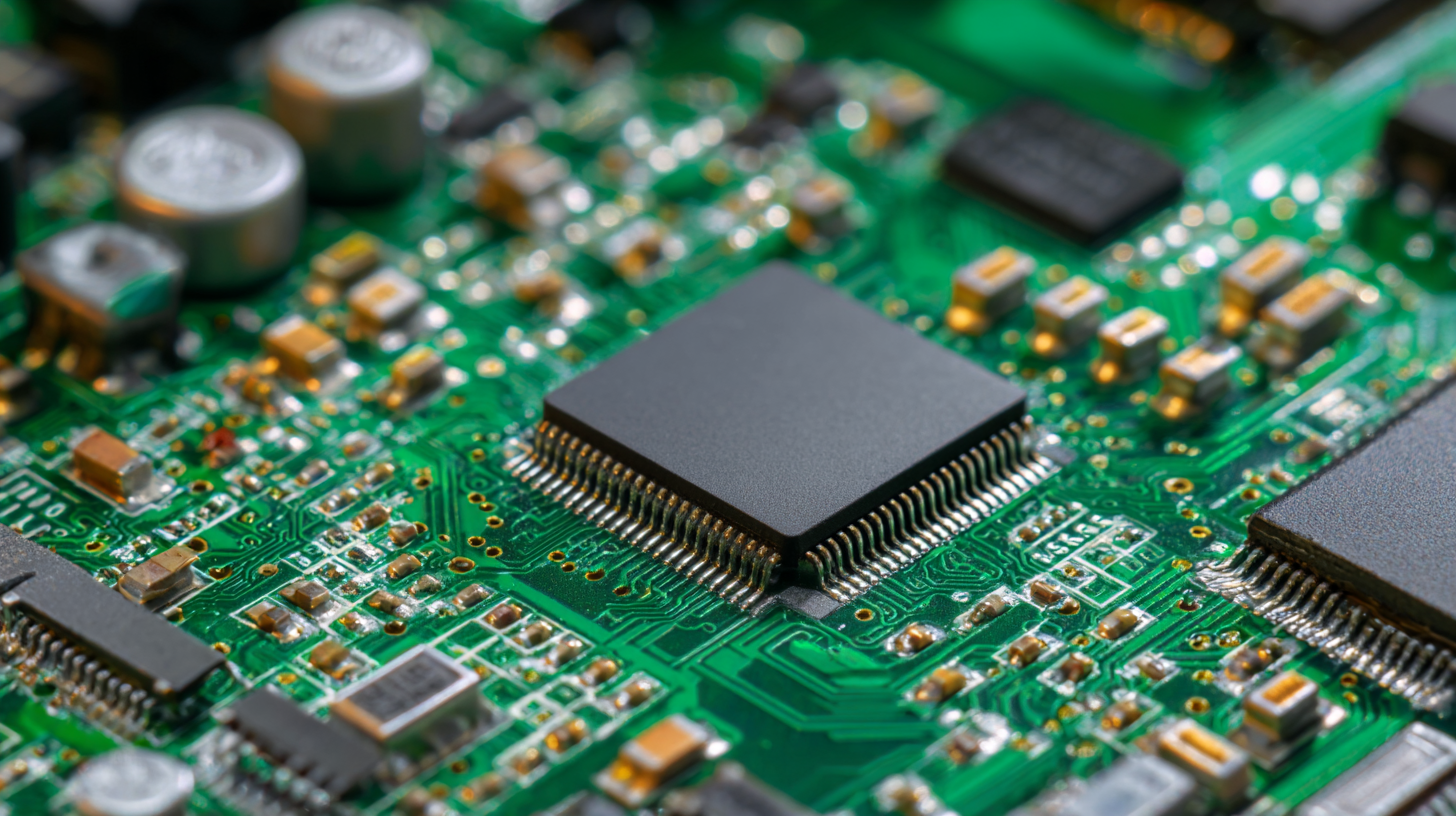

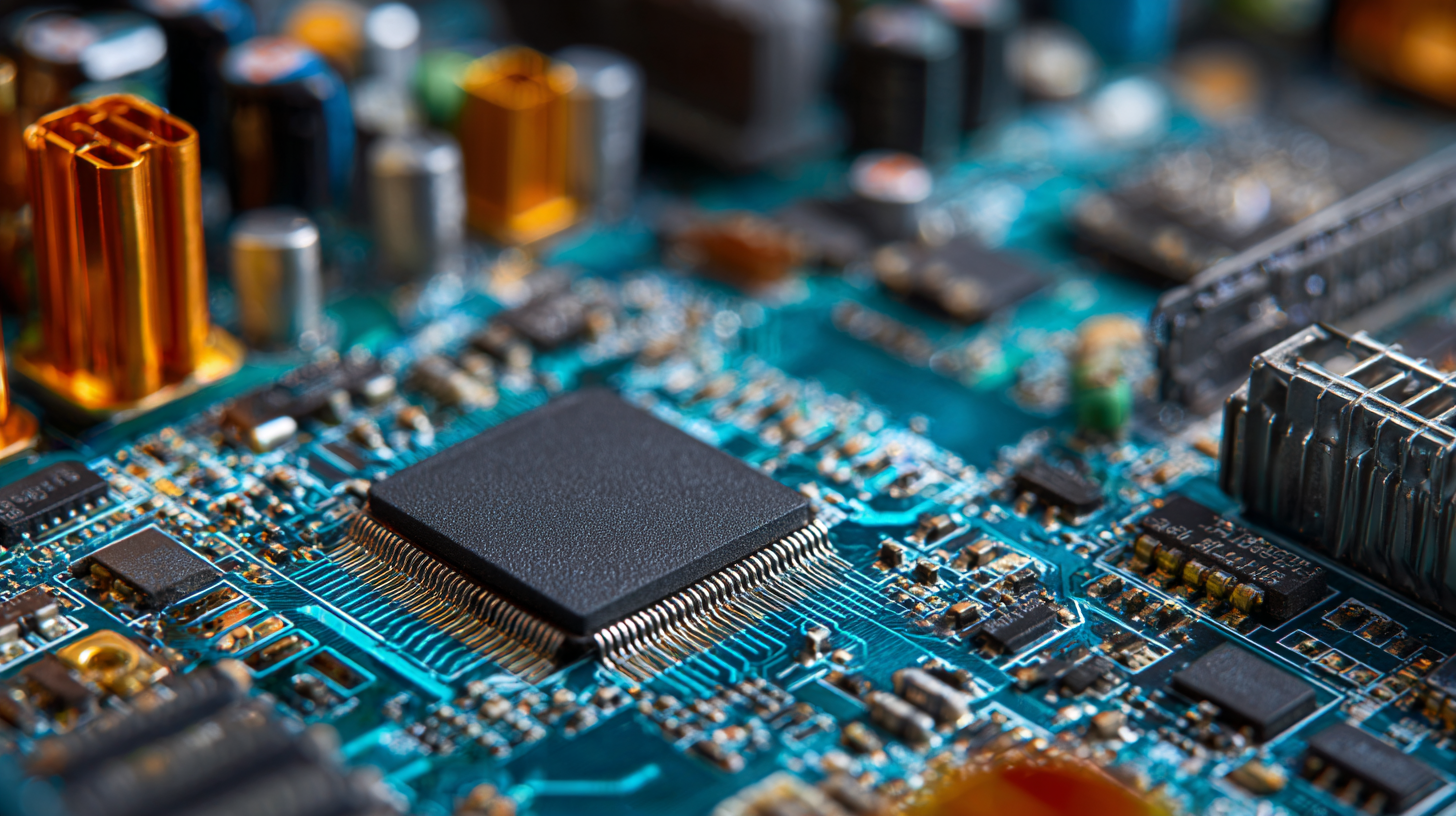

The evolution of PC boards, or printed circuit boards (PCBs), is a fascinating journey that highlights significant advancements in technology. Initially, simple wiring methods were used to connect electronic components, which soon evolved into more sophisticated designs as the demand for compactness and efficiency grew. The introduction of multilayer boards allowed for enhanced routing capabilities, accommodating complex circuits within a limited space. Innovations in materials, such as the transition from paper-based boards to high-frequency laminates, have also played a pivotal role in the development of modern electronics.

Tips for Designing PCBs: Always consider thermal management during the design phase. Proper heat dissipation techniques can greatly enhance the longevity and reliability of your circuit board. Additionally, utilizing simulation software before physical production can save time and resources by identifying potential layout issues early on.

As technology has progressed, the miniaturization of components and increased functionality have led to the rise of flexible and rigid-flex PCBs. These innovations have enabled the integration of circuits into diverse applications, from wearable devices to advanced aerospace systems. Keeping up with the latest trends, such as environmentally friendly materials and methods, is crucial for any designer in the rapidly evolving electronics landscape.

The performance of printed circuit boards (PCBs) is heavily influenced by the materials used in their construction. Typically, PCBs are made from various substrates, including FR-4, polyimide, and Rogers materials, each offering distinct electrical and thermal properties. According to a report by Research and Markets, the global PCB market is expected to reach $83.82 billion by 2025, driven largely by the growth in technology sectors such as telecommunications, automotive, and consumer electronics. The choice of substrate material can significantly influence the overall performance, reliability, and longevity of electronic devices.

FR-4, a glass-reinforced epoxy laminate, is the most commonly used material due to its excellent insulating properties and mechanical strength. However, for high-frequency applications, Rogers materials, often chosen for their low dielectric loss and stable thermal properties, are crucial. A study published by the IEEE highlights that using advanced materials can reduce signal loss by up to 25%, directly impacting the efficiency of high-speed digital circuits.

The continuous evolution of materials science in PCB manufacturing is essential for meeting the demands of modern electronics, ensuring devices operate efficiently in an increasingly complex technological landscape.

The global PCB (printed circuit board) industry is experiencing significant growth, with the market size projected to reach $71.57 billion in 2024. This upward trend is expected to continue as the market expands to $74.12 billion in 2025, ultimately reaching $113.49 billion by 2032. The projected compound annual growth rate (CAGR) of 6.3% reflects the rising demand for PCBs driven by advancements in technology and the increasing adoption of electronics across various sectors.

As digital transformation accelerates and economic stability returns, the PCB industry is positioned to capitalize on these trends. The sector is intricately linked to the broader electronics market, providing crucial support for consumer electronics, automotive applications, and industrial systems. Furthermore, the development of innovative PCB technologies, including flexible and high-density interconnects, is anticipated to further enhance market growth, ensuring that the industry remains at the forefront of modern electronic manufacturing.

The evolution of printed circuit boards (PCBs) reflects significant advancements in modern electronics, but the environmental impact of PCB manufacturing necessitates a shift towards sustainable practices. Traditional PCB production has involved processes that can release harmful chemicals and generate substantial electronic waste. Therefore, embracing eco-friendly materials and technologies has become essential for minimizing environmental footprints.

Sustainable practices in PCB manufacturing include the use of lead-free solder, environmentally friendly substrates like biodegradable materials, and the implementation of energy-efficient production techniques. Manufacturers are also integrating recycling programs to recover valuable metals and reduce waste. By adopting these green innovations, the electronics industry can not only comply with regulatory frameworks but also appeal to environmentally conscious consumers.

Furthermore, the circular economy model encourages continual resource use and recycling, ensuring that PCB production contributes positively to both the marketplace and the planet.

In the rapidly evolving landscape of modern electronics, Printed Circuit Boards (PCBs) are crucial in accommodating the escalating demands of emerging technologies such as AI and 5G. According to industry reports, the PCB market is projected to grow significantly, driven by advancements in semiconductor technologies and an increasing reliance on complex electronic components for devices. This shift is catalyzed by the surging demand for high-performance computing and connectivity, which are pivotal to applications ranging from smart devices to industrial automation.

Emerging trends in PCB design and manufacturing are marked by innovations such as increased miniaturization and enhanced functionality. The recent growth seen in companies within the sector, particularly those focusing on AI capabilities and 5G integration, reflects a broader industry push towards smarter, more efficient designs. For instance, a recent report highlighted that PCB businesses are capitalizing on the proliferation of AI computational needs and the burgeoning low-altitude economy. The ongoing shift towards high-frequency and high-density interconnections in PCBs is not only reshaping the manufacturing landscape but also setting the stage for the next generation of electronic applications. These developments underscore the importance of continuous innovation in PCB engineering to meet future technological challenges.