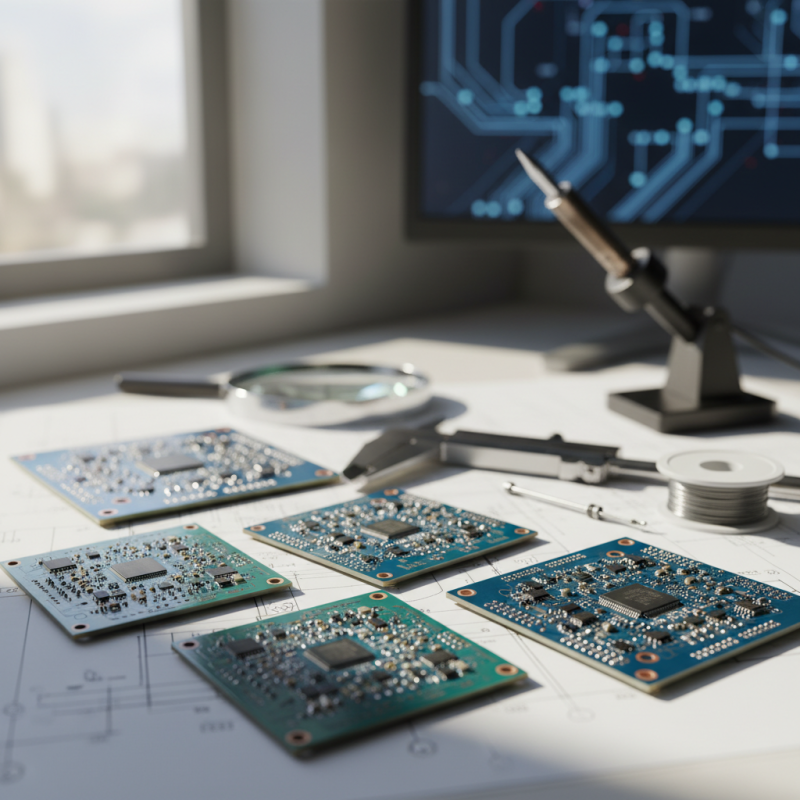

In today's fast-paced electronics industry, speed and efficiency are crucial. Designers often face tight timelines for product development. Quick turn PCB boards provide a vital solution for rapid prototyping. These boards enable engineers to test and iterate their designs swiftly. The ability to produce PCBs quickly can significantly reduce time-to-market for new products.

However, relying solely on quick turn PCB boards has its challenges. Quality must not be sacrificed for speed. Sometimes, manufacturers may overlook critical details in the rush to deliver. This oversight can lead to costly errors and delays. Designers must remain vigilant. They should ensure that their specifications are clear and precise, even in expedited processes.

Ultimately, quick turn PCB boards offer invaluable advantages in prototyping. They foster innovation and enhance competitive edge. Yet, it is essential to balance speed with quality. A thoughtful approach is necessary to truly capitalize on the benefits of rapid prototyping. This method of production demands not only adherence to deadlines but also an unwavering focus on excellence.

Quick turn PCB boards are essential in rapid prototyping. These boards allow designers to create functional prototypes quickly. A recent industry report revealed that over 80% of electronics companies value speed in their prototyping process. Fast turnaround times can significantly enhance a company's ability to innovate.

Key qualities define effective quick turn PCBs. First, manufacturing speed is crucial. Boards must be fabricated within days, rather than weeks. This urgency is often driven by market competition. Quality is non-negotiable. Many manufacturers aim for first-pass success rates above 95%. However, achieving high quality while racing against the clock can be challenging.

Material selection also impacts performance. Using high-quality substrates improves durability and signal integrity. But some designers might cut corners to save costs, leading to potential failures. The balance between speed and quality often requires careful consideration. Neglecting one for the other can result in regrettable outcomes. Quick turn PCB boards are a marvel but require thoughtful execution to truly shine.

This chart illustrates key qualities that define quick turn PCB boards for rapid prototyping solutions, including lead time, cost, layer count, minimum hole size, and maximum board size.

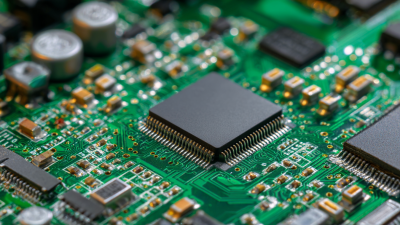

When it comes to rapid prototyping, selecting the right materials for quick turn PCB manufacturing is vital. Many designs require unique specifications that adapt to different applications. Commonly used materials include FR-4, which is versatile and cost-effective. This material is made from woven fiberglass and epoxy resin, ensuring durability and functionality.

Another popular choice is Rogers materials, known for high-frequency applications. They support signal integrity and maintain performance at varying temperatures. However, their cost is a consideration for many projects. Advanced polymers and flexible materials also play a significant role in modern PCB design. They allow for bending or folding, accommodating complex geometric shapes in products.

Tips for your prototyping process: Always specify the thickness of your PCB. Material thickness affects the board's rigidity and overall performance. Another tip is to communicate early with your manufacturer. This can prevent misunderstandings and modifications later on. Lastly, keep in mind that some materials may not be suitable for all environments. Always factor in the end use of your prototypes when selecting the material.

| Material Type | Thickness (mm) | Layer Count | Temperature Rating (°C) | Lead Time (Days) |

|---|---|---|---|---|

| FR-4 | 1.6 | 2 | 130 | 3 |

| Alumina | 0.8 | 1 | 200 | 5 |

| Polyimide | 0.5 | 4 | 260 | 7 |

| CEM-1 | 1.6 | 2 | 120 | 4 |

| PTFE | 1.0 | 2 | 260 | 6 |

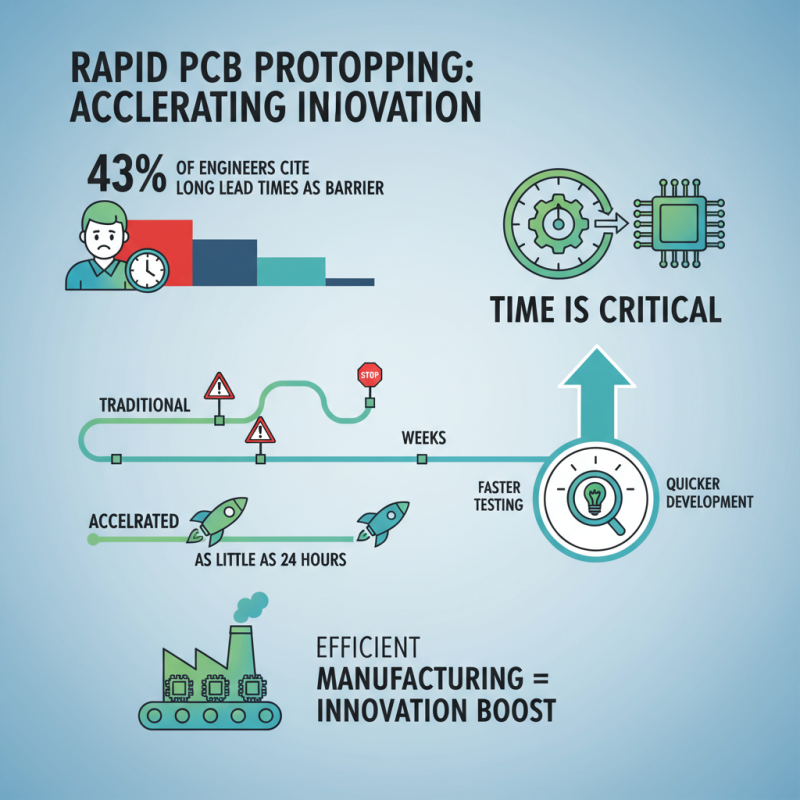

In the world of rapid prototyping, lead time plays a crucial role. A recent study from the IPC estimates that 43% of engineers cite long lead times as a significant barrier to innovation. When time is essential, the ability to quickly produce PCB prototypes can be a game-changer. Companies that leverage efficient manufacturing processes can reduce lead times to as little as 24 hours. This speed not only facilitates testing but also accelerates the overall development cycle.

Many sectors, especially tech and automotive, heavily rely on fast prototyping. Delays can lead to missed market opportunities. According to a survey from MDPI, 66% of firms report that faster prototyping directly influences their product success rate. However, the pressure to reduce lead times can introduce challenges. Quality must not be sacrificed for speed. With tight schedules, mistakes can happen, affecting performance. Engineers must find a balance between quick turnarounds and maintaining high manufacturing standards.

Prototyping isn't flawless. Companies occasionally face setbacks due to unexpected delays or design flaws. Such instances highlight the need for continuous process review. Teams often need to reassess timelines and establish realistic expectations. By fostering a culture of open communication, they can mitigate risks associated with rapid prototyping timelines. Ultimately, reflecting on lead times can drive improvements in both product development and market responsiveness.

In rapid prototyping, striking a balance between cost, speed, and quality is crucial. A recent report from the IPC states that quality issues can increase production costs by up to 30%. When speed becomes the priority, there is often a trade-off in quality. For instance, using thinner materials can expedite production but may lead to delamination issues later.

Mismatched expectations can arise when companies prioritize quick turnaround times over thorough testing. Many manufacturers offer quick turn services, but they might compromise on the testing protocols essential for ensuring performance. According to a survey conducted by PCB West, 65% of engineers reported encountering defects in PCBs rushed into production.

Investing in quality assurance can mitigate some of these risks. In many cases, up to 20% of the total project budget should allocate to quality checks. Some companies may find that a slight increase in production time yields significantly more reliable results. In the fast-paced world of prototyping, reconsidering what speed truly brings to your project could save time and money in the long run.

The demand for quick turn PCB boards has surged, fueled by rapid technological advancements. In a recent report, 75% of engineers noted faster design cycles as a critical factor in their prototyping efforts. This shift is reflecting broader trends in electronics where speed often trumps perfection. Design teams now prioritize speed over extensive testing phases. Such changes prompt a rethink of traditional processes.

Innovations like automated design tools enhance efficiency significantly. PCB design software with built-in simulation capabilities can reduce time spent on revisions. As per industry studies, these tools can decrease design iteration time by 40%. However, reliance on automation raises concerns. Errors may slip through undetected, leading to potential failures in the field. Balancing speed with quality becomes a challenge for many engineers.

The PCB manufacturing process is also evolving. Advanced techniques such as high-density interconnect (HDI) are making boards smaller and more complex. However, they come with challenges in fabrication. Some manufacturers struggle to maintain quality in fast-tracked production lines. A recent survey indicated that 30% of companies reported defects in rushed PCB boards. This signifies that while technology streamlines processes, it can also introduce new risks that need careful management.