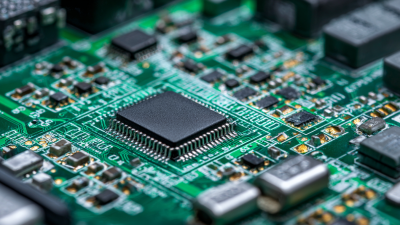

In today's fast-paced electronics industry, quick PCB fabrication is essential. Experts like Dr. Emily Wong emphasize its importance, stating, "Speed and precision are vital in PCB prototyping." With rapid production cycles, manufacturers can improve their product development timelines significantly.

Quick PCB fabrication techniques vary widely, ranging from advanced technologies to simpler methods. Many companies overlook basic practices that can enhance speed. For instance, optimizing design files can prevent delays during production. Moreover, choosing the right materials contributes to faster turnaround times. However, not all methods guarantee high quality, leading to potential issues later.

Relying solely on speed can compromise the integrity of the PCB. Errors in the early stages may result in costly revisions later. It is crucial to balance fast prototyping with quality assurance. This involves careful planning and an understanding of each technique's limitations. By tackling these challenges, manufacturers can embrace quick PCB fabrication while still meeting high-quality standards.

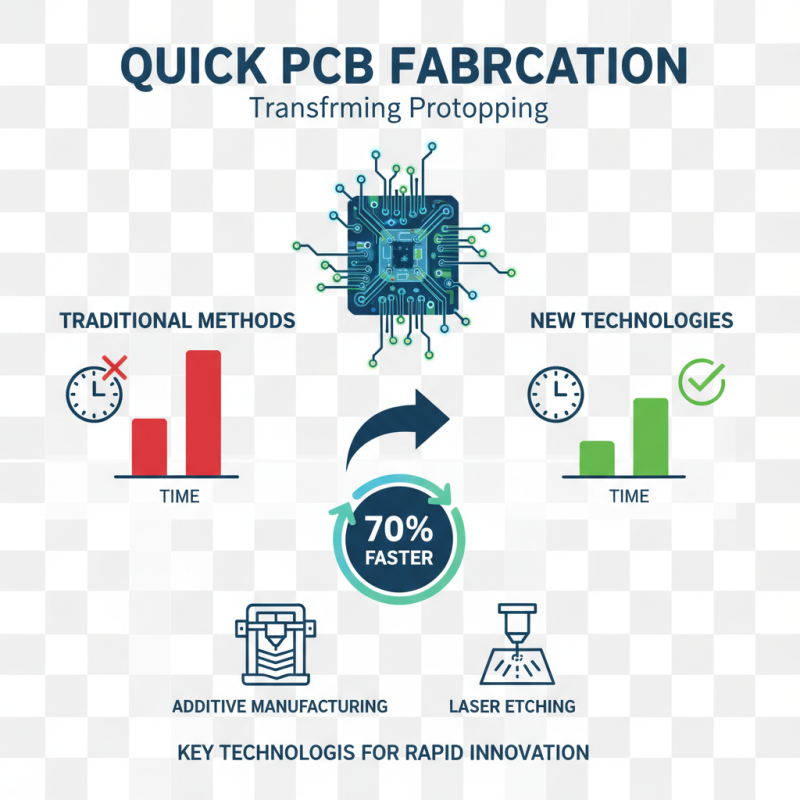

In the fast-paced world of electronics, rapid prototyping is essential. PCB fabrication techniques have evolved significantly, allowing engineers to meet market demands quickly. According to a recent industry report, 70% of companies prioritize speed in PCB prototyping to stay competitive. This shift requires understanding various techniques that enhance efficiency.

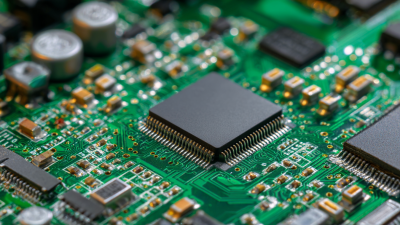

One popular method is CNC machining. This technique can produce PCBs in just a few hours. However, it demands precision—a small error can lead to significant issues. Another technique is additive manufacturing, also known as 3D printing. It simplifies the creation of complex designs but may face limitations in material quality.

Tip: Always test your designs multiple times. Small flaws might go unnoticed but can lead to larger problems in the final product.

Additionally, laser etching provides rapid results, particularly for multilayer boards. The process is quick but can be costly. Balancing speed and cost is always a challenge. Finding the right technique can be overwhelming.

Tip: Keep your documentation organized. This habit improves communication and helps avoid missteps.

Using a combination of these methods can lead to faster iterations. However, engineers often struggle with choosing the best fit for their needs. Evaluate your requirements carefully to avoid wasted resources and time.

Quick PCB prototyping plays a crucial role in modern electronic design. Engineers often face tight deadlines. Rapid iterations can lead to quicker insights. This process allows designers to test ideas without lengthy delays. The speed of prototyping enables faster product development cycles.

Understanding quick prototyping helps teams identify design flaws early. Mistakes discovered late in the process can be costly. Immediate feedback helps improve designs on the fly. However, rushing can lead to oversights. Some details might be neglected in the haste. A balance between speed and quality is essential.

The significance of quick PCB fabrication extends beyond mere speed. It fosters innovation and creativity. Teams can adjust designs based on real-world performance. Yet, initial prototypes might not be perfect. This imperfection can inspire further exploration and refinement. Prototyping becomes a learning experience that enhances overall project outcomes.

| Technique | Description | Speed (days) | Applications |

|---|---|---|---|

| Direct PCB Printing | Utilizes inkjet technology for direct printing of PCB layouts. | 1-2 | Simple prototypes, educational projects. |

| Laser Etching | Uses a laser to etch copper layers from a PCB board. | 2-3 | Detailed designs, low-volume runs. |

| CNC Milling | Removes material from copper-clad boards using CNC machines. | 3-5 | Custom designs, quick iterations. |

| Photoresist Process | Uses light-sensitive materials to create circuitry designs. | 4-7 | Complex circuits, standard production. |

| Rapid PCB Prototyping Services | Outsourcing PCB fabrication to specialized prototyping companies. | 5-10 | Consumer electronics, device testing. |

| Flexible PCB Technology | Allows for adaptability in design and application. | 5-8 | Wearable devices, compact electronics. |

| Screen Printing | Involves applying conductive ink through a screen onto the board. | 2-4 | Prototyping simple circuits, low-cost production. |

| Vapor Deposition | Deposits metal layers on substrates using vaporization technology. | 6-10 | High-performance applications, RF designs. |

| 3D Printed PCB | Creates boards using 3D printing technology with conductive materials. | 3-6 | Customization, unconventional shapes. |

| Hybrid PCB Technology | Combines various materials and methods for enhanced performance. | 4-8 | Advanced applications, high-frequency circuits. |

In the world of electronics, quick PCB fabrication techniques are essential.

Rapid prototyping saves time and resources. Many methods exist, each with its own benefits and drawbacks.

One popular approach is using CNC machines. They provide precise cuts and can produce complex designs. However, the setup time can be lengthy.

Another technique involves laser etching. This method is faster, but it may lack the accuracy for intricate patterns.

3D printing of PCBs is gaining traction too. It allows for swift iterations and can produce multi-layer boards.

Yet, the materials used might not always meet durability standards. Each method requires careful consideration of project needs.

Balancing speed with quality is often tricky. Experimenting with various techniques can yield surprising results, but perfection is rarely achieved on the first try.

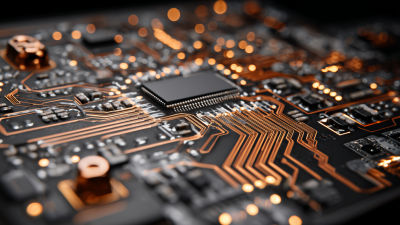

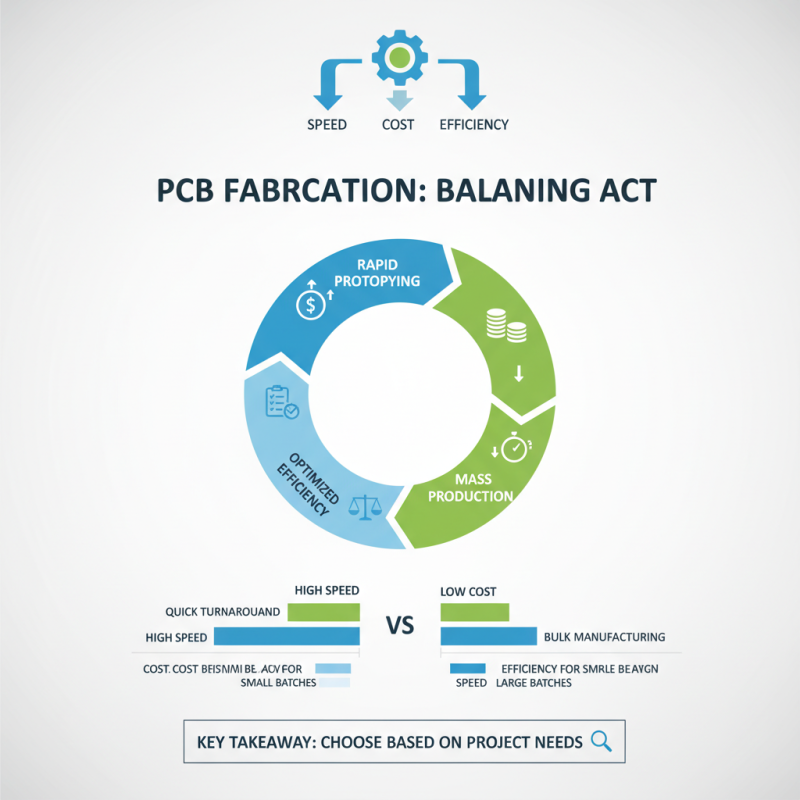

In the world of PCB fabrication, speed, cost, and efficiency are crucial. When comparing techniques, each method has its strengths and weaknesses. Some techniques may promise rapid results but can drive costs up. Others prioritize affordability while lagging in execution speed. It's essential to assess the specific requirements of each project to find the right balance.

For example, laser manufacturing offers quick turnarounds. However, it may not always produce the finest resolution. Conversely, traditional methods can yield high precision but often involve longer lead times. Rapid prototyping methods, such as CNC milling, strike a decent balance. They deliver moderate speed and satisfactory cost-effectiveness but may leave room for improvement in efficiency.

A reflective approach is vital. Consider the end application of the PCB. A hasty approach might result in compromised quality. It's often necessary to revisit the chosen technique, ensuring it aligns with project goals. This reflection can lead to better decisions in future prototyping efforts. Exploring new methods and improving older ones can create opportunities for innovation.

In recent years, quick PCB fabrication has transformed the prototyping landscape. Advanced technologies like additive manufacturing and laser etching are paving the way. Reports suggest that these methods can reduce fabrication time by up to 70%. This speed is crucial in competitive markets.

Emerging trends see innovations focusing on automated processes. Automation not only enhances speed but also minimizes human error. A study from an industry analyst indicates that over 30% of prototyping failures stem from manual inaccuracies. Emphasizing automated systems can lead to more efficient workflows.

Tips: Utilize rapid prototyping tools. Regular maintenance of equipment is essential. Consider sharing designs online for collaborative feedback. Future developments are leaning toward eco-friendly materials. Sustainable practices are set to reshape industry standards, appealing to a more conscious consumer base. Stay updated on these evolving trends.