In the fast-paced world of electronics manufacturing, efficient PCB assembly is crucial. According to a recent industry report by IPC, the global PCB market is expected to reach $75 billion by 2026, driven by advancements in technology and increasing demand for electronic devices. Yet, many manufacturers still face challenges in their assembly processes, leading to costly delays and reduced competitiveness.

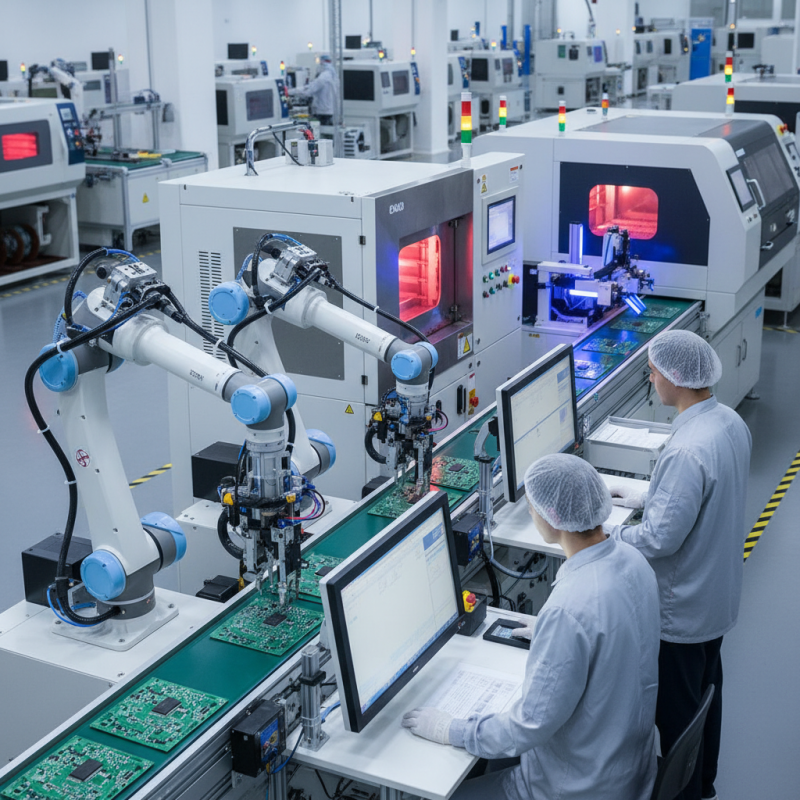

Improving PCB assembly practices can significantly enhance productivity. However, several companies overlook basic principles, resulting in inefficiencies. For instance, proper component placement can shorten assembly time by 35%. Neglecting this can lead to wasted resources and labor. Additionally, integrating automated processes may seem daunting but can yield significant benefits in accuracy. Reports indicate that automation reduces assembly errors by up to 50%, yet many firms still shy away from these investments.

Addressing these common pitfalls is essential. Failing to conduct regular quality checks can lead to defects that escalate costs. As manufacturers strive to keep up with market demands, understanding how to optimize PCB assembly is vital. By implementing key strategies, businesses can not only reduce errors but also enhance their overall production efficiency.

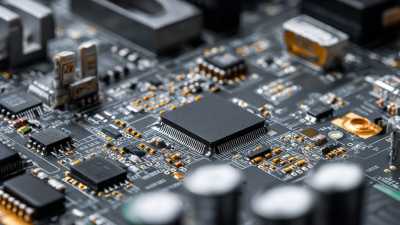

PCB assembly is a complex process that often presents various challenges. One common issue is component misalignment. Ensuring that components are placed correctly can prevent costly errors. Regularly checking alignment during assembly can help catch mistakes early. Another challenge is managing thermal issues. Overheating can damage sensitive components. Monitoring temperature levels throughout the process is essential.

Cleaning the PCB before assembly is often overlooked. Dust and debris can lead to improper connections. A thorough cleaning regimen can significantly reduce this risk. Additionally, inconsistent solder quality is a frequent problem. It can result in weak connections or shorts. Investing in high-quality solder and regular testing can help maintain standards.

Communication among team members is also crucial. Misunderstandings can lead to mistakes and project delays. Routine meetings can enhance collaboration and address potential issues. Documenting processes may also highlight areas for improvement. Sometimes, teams forget to review past projects. Learning from previous mistakes fosters better practices over time. Embracing these strategies can lead to more efficient PCB assembly.

Choosing the right PCB assembly partner is crucial for efficient manufacturing. A 2022 industry report highlighted that 45% of companies faced delays due to poor communication with their assembly partners. When selecting a partner, evaluate their communication channels. Clear, open lines help in addressing issues promptly.

Consider the partner's experience. Companies with over five years in the industry handle complexities better. They often have established workflows that enhance productivity. Another study noted that seasoned partners reduce production costs by up to 25%. However, don't overlook smaller firms. They might provide personalized service that larger companies can't match.

Check for certifications as well. A partner with ISO 9001 certification shows commitment to quality. However, be cautious. Some companies flaunt certifications without adhering to standards. Lastly, ensure they have a solid supply chain network. Disruptions in sourcing components can lead to delays. Opt for partners with diversified suppliers to mitigate risks.

| Tip Number | Tip | Description | Impact on Manufacturing |

|---|---|---|---|

| 1 | Design for Manufacturability | Optimize PCB layout to reduce assembly time | Decreases production costs and improves turnaround time |

| 2 | Select the Right Materials | Choose components that are easy to assemble | Enhances reliability and sustainability of the product |

| 3 | Utilize Automated Assembly | Implement automated machines for assembly processes | Increases efficiency and reduces human error |

| 4 | Establish Clear Communication | Ensure all stakeholders are aligned | Reduces misunderstandings and speeds up project timelines |

| 5 | Quality Control Processes | Implement rigorous quality checks | Minimizes defects and recalls |

| 6 | Invest in Training | Train staff in the latest assembly techniques | Improves overall quality and efficiency |

| 7 | Regular Equipment Maintenance | Maintain and calibrate assembly machines | Ensures consistent performance and reduces downtime |

| 8 | Prototyping | Create prototypes to test designs before full-scale production | Identifies issues before mass production, saving time and cost |

| 9 | Sourcing Reliable Suppliers | Build relationships with trustworthy suppliers | Ensures quality inputs and timely deliveries |

| 10 | Feedback Loop | Establish a system for collecting feedback post-production | Helps in continuous improvement of processes |

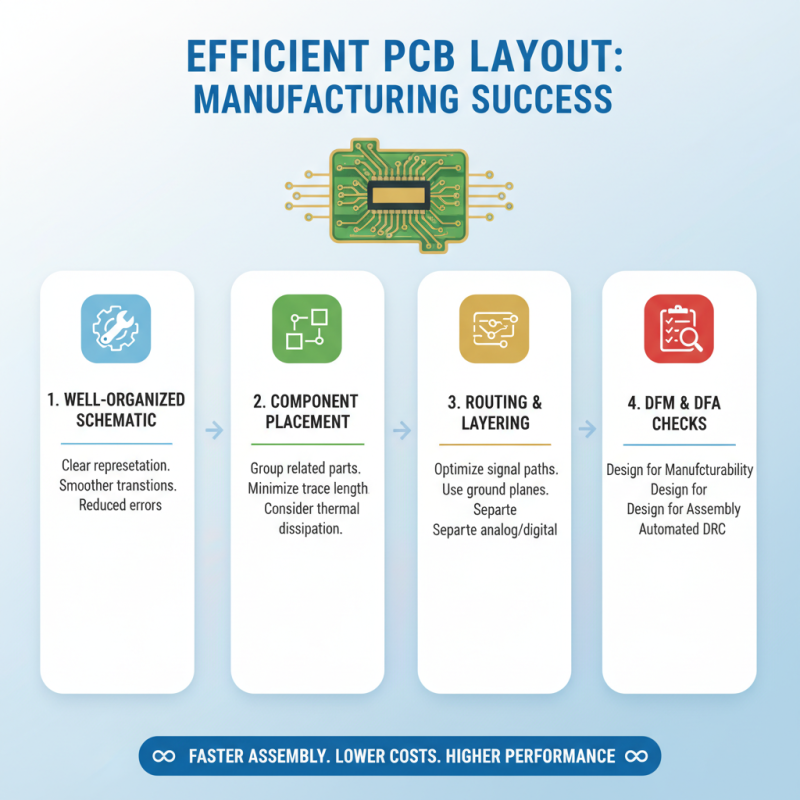

Designing an efficient PCB layout is critical for successful manufacturing. Proper layout not only influences performance but also affects assembly speed and cost. Start with a well-organized schematic. A clear representation makes transitions smoother and reduces errors.

One essential tip is to minimize trace lengths. Longer traces can lead to increased resistance and interfere with signals. Keep components that communicate with each other close together. This reduces the space needed and lowers the risk of signal degradation. Additionally, consider incorporating vias sparingly. Too many vias can complicate the design and slow down the manufacturing process.

Thermal management is often overlooked. Ensure that components generating heat are spaced adequately. This helps maintain optimal performance. Using thermal vias or copper pours can be beneficial. However, don't overcomplicate your design. A clean layout can sometimes be more effective than an overly intricate one. Always review and refine your design before finalizing to avoid potential pitfalls.

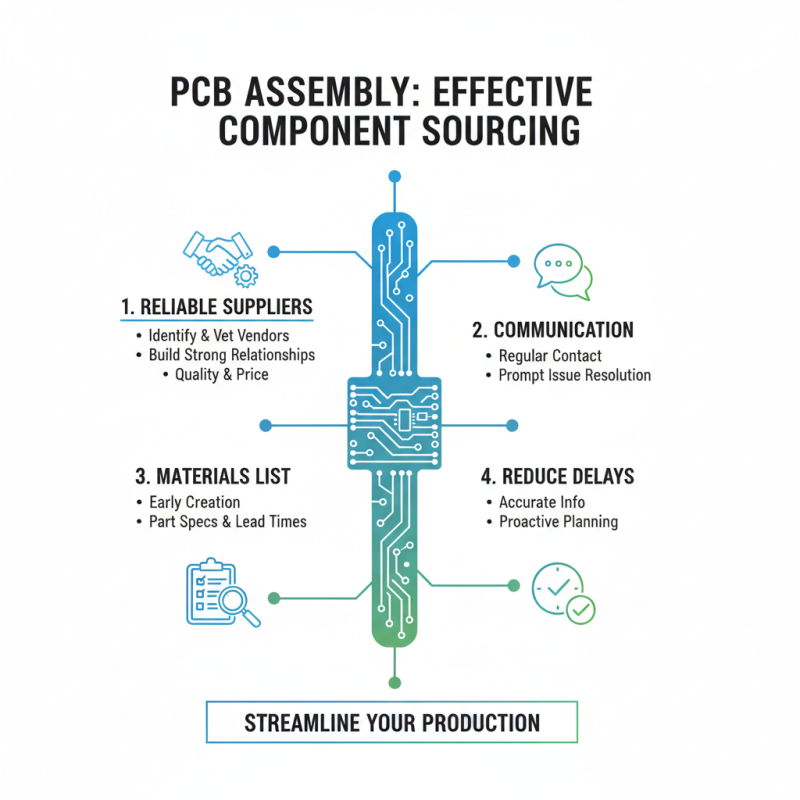

Effective component sourcing is crucial in PCB assembly. Begin by identifying reliable suppliers. Building strong relationships with vendors can ensure quality parts at reasonable prices. Regular communication helps address issues promptly. Creating a materials list early is essential. This list should include part specifications and lead times. Accurate information reduces the risk of delays.

Inventory management plays a key role. A well-organized system can prevent overstocking or shortages. Track component usage to forecast future needs. Often, manufacturers underestimate this aspect. Mistakes in forecasting can lead to project delays and added costs.

Flexibility in sourcing is also important. Seek alternative suppliers for critical components. Diversifying sources can mitigate risks, especially during shortages. It is wise to remain adaptable when faced with unexpected changes in the supply chain. Regularly review sourcing strategies. Reflect on what works and what doesn’t. Continuous improvement is vital for efficient manufacturing.

In PCB assembly, quality control is crucial. Monitoring every step prevents defects. Regular inspections help identify issues early. Visual checks are essential for solder joints. Operators should be trained to spot common mistakes.

Implementing automated testing can increase efficiency. However, relying solely on machines may introduce new errors. Mistakes can happen in programming. Human oversight is still necessary. Different test methods can ensure thorough evaluation.

Documentation plays a vital role. Record-keeping allows for tracing back issues. Errors in previous batches can inform future production. However, maintaining accurate records demands discipline and attention to detail. Teams often overlook this aspect. Quality control is a continuous improvement process. Each assembly cycle offers lessons for future enhancements.