In today's rapidly evolving tech landscape, the field of PCB manufacturing and assembly is experiencing significant changes. As industries grow, the demand for advanced circuit boards increases. Trends are shaping how companies design, produce, and assemble these crucial components.

One key trend is automation in the manufacturing process. It enhances efficiency and reduces errors. Another vital trend is miniaturization. Devices are becoming smaller, leading to innovative PCB designs. Manufacturers must adapt swiftly to these trends or face losing market share.

Sustainability is now a priority, prompting companies to explore eco-friendly materials. However, this quest for greener options presents challenges in sourcing and performance. The evolving landscape of PCB manufacturing and assembly requires constant vigilance. Businesses must reflect on their decisions and strategies to stay competitive. Awareness of these trends is essential for future success.

In the rapidly evolving world of PCB manufacturing and assembly, staying updated is crucial. One key trend is the rise of automation. Factories are increasingly using robots for repetitive tasks. This not only speeds up production but also enhances precision. However, it’s important to remember that automation can lead to skill gaps in the workforce.

Another trend is the push for sustainable practices. Many manufacturers are focused on reducing waste and energy consumption. For instance, some are adopting eco-friendly materials in their production processes. This approach not only attracts environmentally conscious clients but also complies with emerging regulations. Though, transitioning to greener methods can be challenging and costly.

Tip: Regularly assess your production processes. Look for waste reduction opportunities without compromising quality.

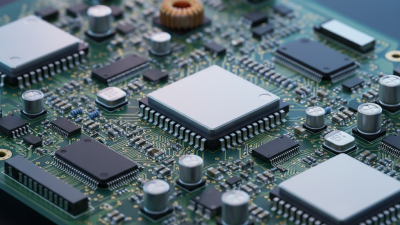

The trend towards smaller and more complex designs is also significant. Devices today require intricate PCB layouts. This can make manufacturing more difficult. Engineers need to be highly skilled and versatile. Yet, the pressure to innovate can lead to increased errors.

Tip: Invest in training for your team. Ensure they are up to date on the latest technologies and design techniques.

The rise of flexible PCB technologies is reshaping consumer electronics. According to recent reports, the flexible PCB market is expected to grow at a compound annual growth rate (CAGR) of over 13% from 2023 to 2030. This trend reflects a growing demand for lightweight and compact device designs. Companies in various sectors are leveraging this technology to enhance product functionality and durability.

Flexible PCBs are ideal for devices with limited space and shifting environments. Wearable technology and smartphones are prime examples. These circuits can bend and fold without losing performance. However, transitioning to flexible PCBs can be challenging. Manufacturers must adapt their production methods and design processes to accommodate this technology.

Tips: When considering flexible PCBs, analyze the specific requirements of your products. Understand the mechanical and electrical properties needed. Collaborate closely with your design team to troubleshoot any potential issues early in the development process. Embracing flexible PCBs could lead to innovative product solutions but requires careful planning.

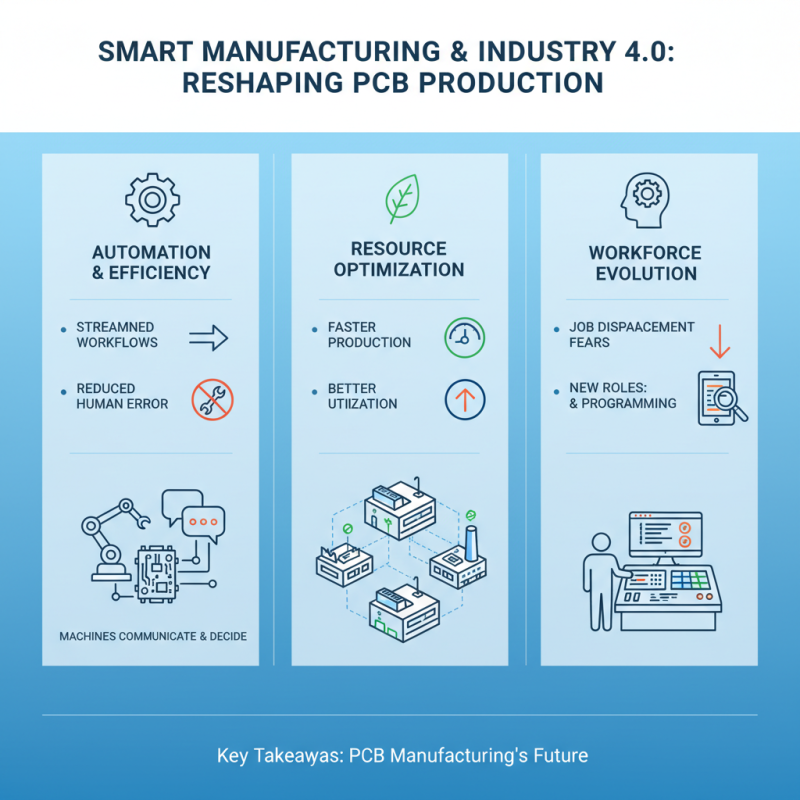

Smart manufacturing and Industry 4.0 are reshaping PCB production dramatically. Automation is becoming commonplace, streamlining workflows and reducing human error. Machines communicate and make decisions faster than before. This efficiency leads to better resource utilization, but it also raises concerns about job displacement. Workers need to adapt to new roles focused on oversight and programming.

The implementation of IoT devices enhances monitoring during the PCB assembly process. Real-time data allows manufacturers to adjust parameters instantly. Issues can be detected before they escalate, improving quality control. Yet, data security becomes a pressing concern. With increased connectivity, vulnerabilities may be exposed, risking sensitive information.

Despite advancements, some barriers remain. Adopting smart technologies requires high initial investment. Not every manufacturer can ensure a seamless transition. Training workers on new systems presents challenges, often met with resistance. There is much to explore in balancing innovation with human factors. Embracing change is vital, but it isn’t without its difficulties.

Automated Optical Inspection (AOI) systems are gaining traction in PCB manufacturing and assembly. These systems enhance quality control by using high-resolution cameras to inspect printed circuit boards. Reports indicate that the adoption of AOI technology has increased by over 25% in the past three years. This shift is driven by the need for precision in a competitive market.

Despite its advantages, AOI is not foolproof. Some reports suggest that false positives from AOI can lead to wasted resources. For instance, misidentifying good components as defective can stall production lines. It's essential for manufacturers to balance automation with human oversight to mitigate these errors. A well-implemented AOI system should serve as a supplement, not a complete replacement for traditional inspection methods.

Moreover, while AOI can identify physical defects, it struggles with certain issues. Problems like solder joint quality may not be detected by vision systems alone. Manufacturers must continuously adapt and refine their processes. Embracing AOI means committing to ongoing training and improvements. Only then can the full potential of this technology be realized.

The demand for sustainability in PCB manufacturing is growing. Eco-friendly materials are becoming a priority. Biodegradable substrates are gaining traction. These materials reduce waste and environmental impact significantly. They often utilize natural fibers and resins, which are less harmful than conventional options.

Processes are also evolving. Manufacturers are exploring water-based inks and coatings. These options are less toxic, posing fewer risks to workers and the environment. Energy-efficient machinery is increasingly standard, cutting down on power usage. However, the transition is not always smooth. Cost implications can be a barrier. Not all companies can pivot quickly.

Looking ahead, the industry must focus on improvement. Recycling printed circuit boards is still a challenge. Many materials remain difficult to reclaim. Awareness must grow about the circular economy. The shift to sustainable practices requires widespread commitment. This is a complex journey, with many lessons still to learn.

The landscape of PCB manufacturing and assembly is evolving rapidly, driven by several key trends. One notable development is the rise of flexible PCB technologies, particularly in consumer electronics, which allows for more versatile and compact designs. Additionally, the integration of smart manufacturing and Industry 4.0 practices is enhancing production efficiency and precision within the PCB sector.

Moreover, there is a growing reliance on Automated Optical Inspection (AOI) systems, which improve quality control and reduce manufacturing errors. Sustainability is also becoming a priority, with an increasing focus on eco-friendly materials and processes. Finally, the demand for high-frequency PCBs is surging, particularly in communication devices, reflecting the need for faster data transmission and improved performance in an increasingly connected world. These trends collectively highlight the innovative advancements shaping the future of PCB manufacturing and assembly.