As electronics become more compact and powerful, manufacturers are constantly looking for efficient ways to build reliable and high-performance circuit boards. One of the most important advancements in this area is Surface Mount Technology (SMT)—a method that has revolutionized PCB manufacturing by making assembly faster, more cost-effective, and scalable.

At YIC Technologies, we specialize in surface mount technology solutions that streamline production and deliver exceptional quality across a wide range of electronic applications.

What is Surface Mount Technology?

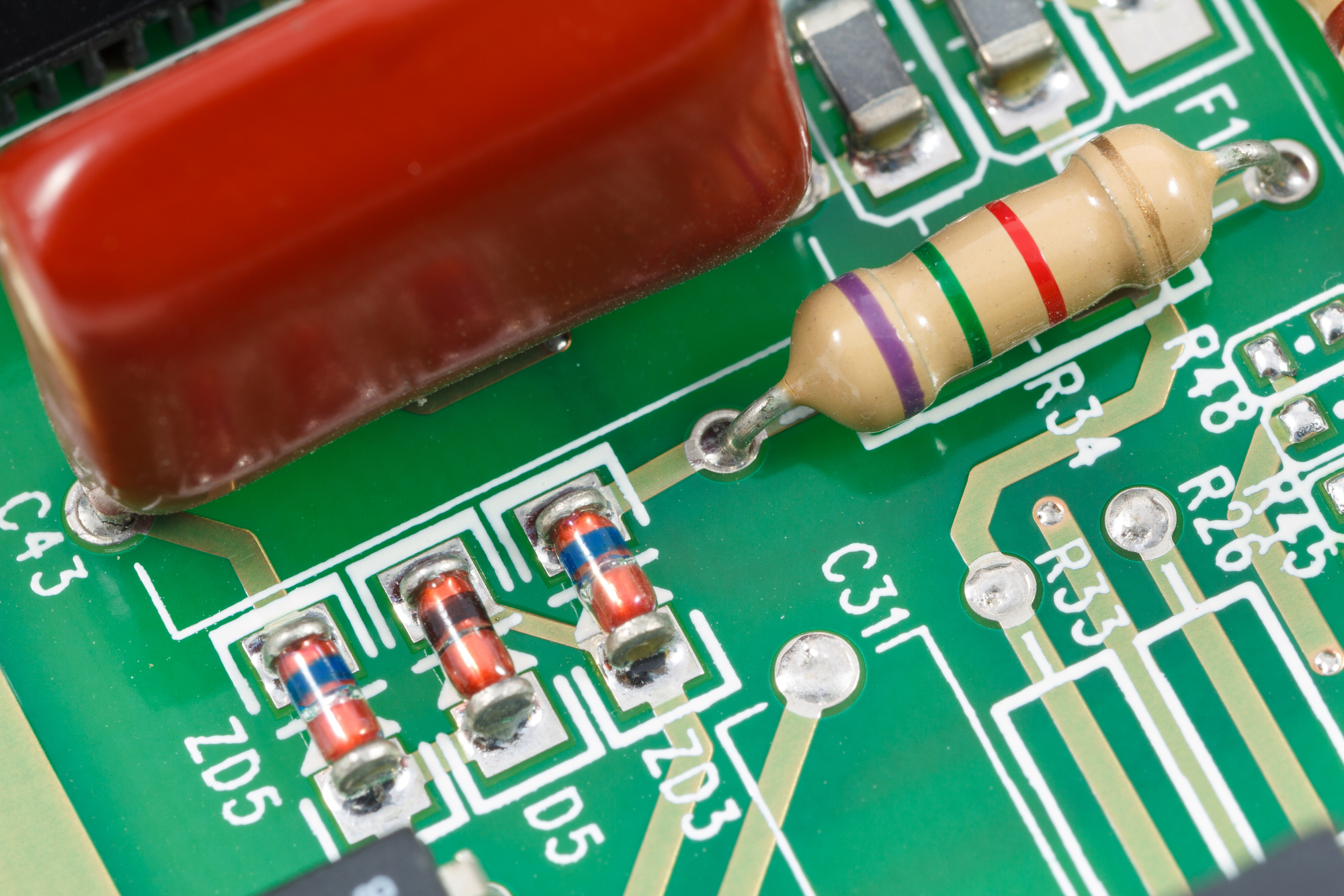

Surface Mount Technology is a method for producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole methods that require wires to pass through drilled holes, SMT components are placed and soldered onto the board’s surface using automated equipment.

Key Benefits of SMT in PCB Manufacturing

1. Smaller, More Compact Designs

One of the most noticeable benefits of SMT is the ability to create smaller and more compact devices. Because components don’t need long leads or holes, more of them can fit in a smaller area. This is especially useful in smartphones, tablets, and wearable tech.

2. Faster Production Speeds

With automated machines handling the placement and soldering of components, SMT significantly reduces manufacturing time. This allows companies like YIC to complete large-scale projects quickly and efficiently, helping clients get their products to market faster.

3. Cost Savings

By eliminating the need for drilling holes and using fewer materials, SMT helps reduce overall production costs. It also reduces manual labor, which translates into further cost savings for customers.

4. Improved Performance

SMT components generally have lower resistance and inductance at the connection, which improves the speed and performance of the circuit. This is ideal for high-frequency applications and modern electronics that demand reliable, high-speed connections.

5. Higher Reliability

Surface-mounted components are less prone to vibration and mechanical wear, resulting in longer-lasting and more durable PCBs—particularly important in aerospace, automotive, and medical devices.

Ready to Upgrade Your PCB Manufacturing?

If you’re seeking a reliable partner for surface mount technology services, YIC Technologies is here to help. With years of expertise and a focus on precision and quality, we’re committed to advancing your electronic innovations.